-

Home

- Products

- News

-

Video

-

Case

-

Contact Us

- About Us

The hydrogenation system usually involves a three-phase slurry, the solid catalyst in slurry phase and the hydrogen bubbles as the gas phase. As there are a number of phase boundaries the mass transfer, and especially the hydrogen dispersion, is a very factor. The mixing system that is employed in the reactor influences the mass transfer coefficient of the gas-liquid transfer greatly.

Lab vacuum reactor | Scale up hydrogenation pilot plant | Autoclave and autoclave system

Pressure reactor systems | High pressure system | Hydrogenation system

? Lab to pilot scale production.

? Max pressure: 300 bar; Max temperature up to 500 ℃

? Available material:SS304, SS316, Titanium, Nickel, Hastelloy B/C, Monel, Zirconium, Inconel, Tantalum.

? Low to high torque magnetic couplings: static seal with no leakage.

? Complete gas consumption; High productivity; Uniform suspension of the catalyst.

? Gas self-inducing impeller; Flat blade turbine impeller; Axial impeller;

? Customized according to customers requirement.

Capacity: 0.5L~500L

Main material:SS304, SS316,Titanium, Nickel, Hastelloy B/C,Zirconium

Pressure: Hydrogenation at 1 ~ 300 bar

Temperature: -20~500℃

Sealing type: Magnetic coupling drive

Heating type: Oil electric heating

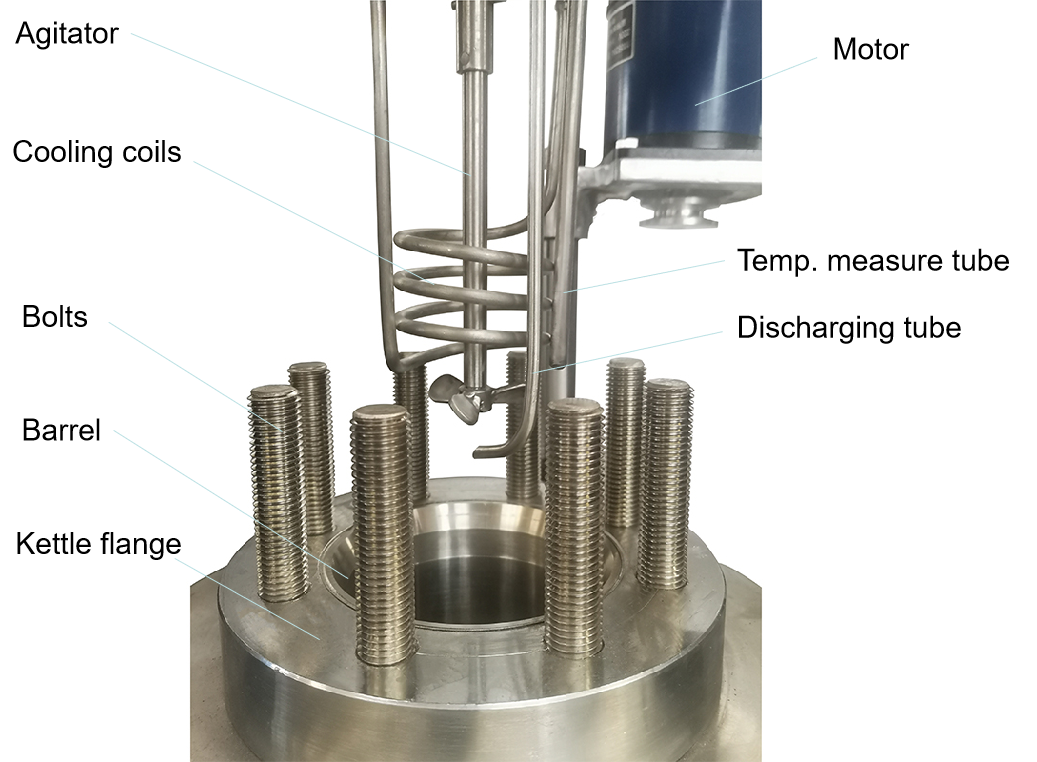

Standard fittings: Pressure Gage; Thermocouple; Internal Stirring System; Liquid inlet and gas inlet with needle valve;Gas Release Valve; Dip Tube; Safety Rupture Disc; Cooling Coil

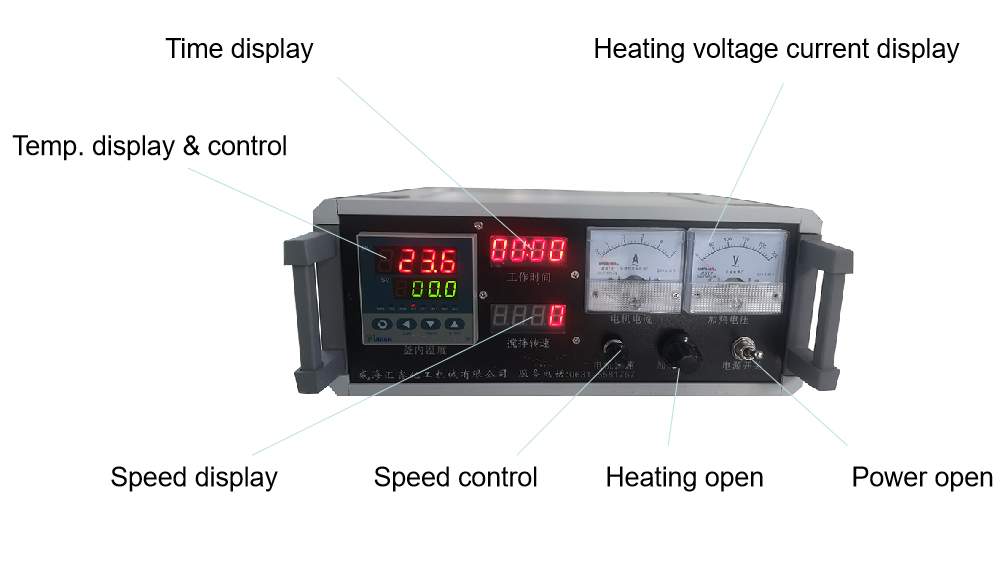

Control system: Control / display of pressure, temperature, stirrer speed

Automatic functions as Nitrogen purging, inertisation

Sequence program (including venting valve) to define automated process steps with possibility to link these, as an example:

Structure Drawings

Control System

Internal Components

Departure Port: Qingdao Port or Shanghai Port

Time of Delivery:

Name | Est.time (Days) |

Lab instru. | <7 |

Pilot plant | <20 |

Industrial | <40 |

Note:The specific delivery date subject to product specifications and quantity.

Payment Terms:

Payment amount | ≤10000USD | >10000USD |

Payment term | 100% TT in advance | 40% T/T in advance, balance before shippment. |

Other type | Paypal;Alibaba | 100% Irrevocable L/C at Sight |

Note: The specific payment terms will be confirmed through negotiation.

Package type:

Wooden Box Packaging (Standard export package)

Application: By air; LCL(Less container loading) by sea.

Details:The product will be covered by PE film, then packed in plywood case. If necessary, steel frame outside support and steel wire inside fixing.