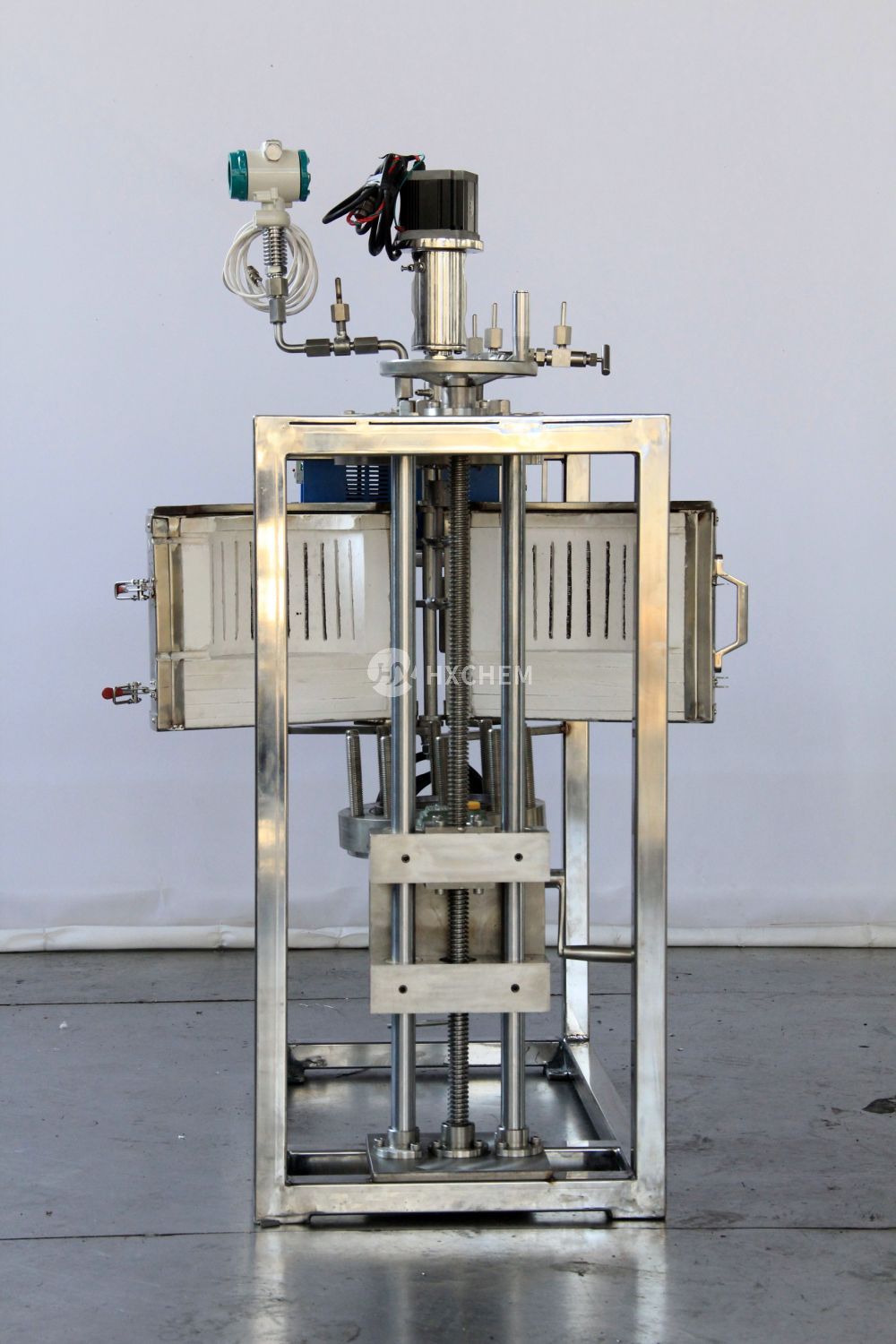

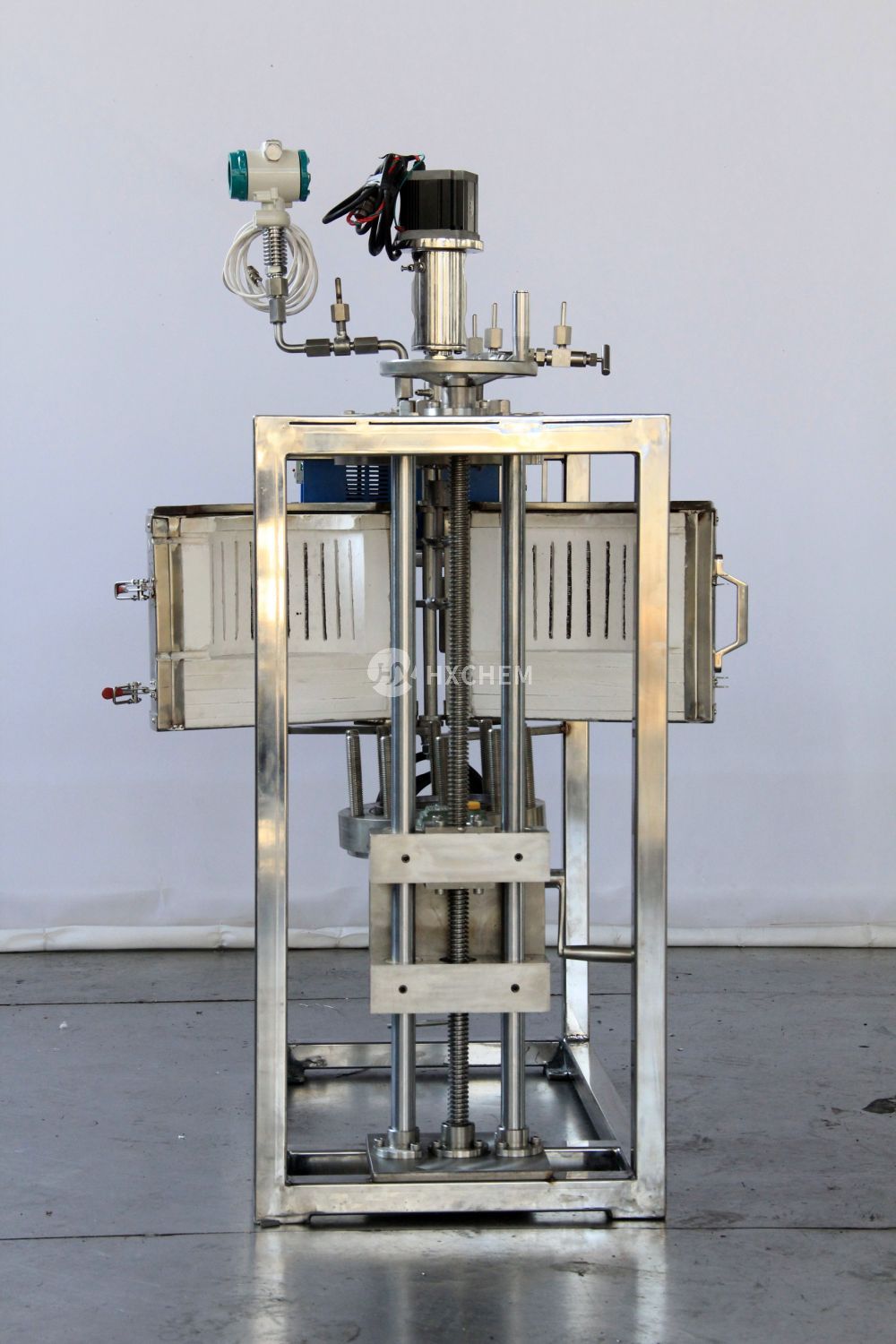

3L high pressure lab tantalum reactor

3L high pressure lab tantalum reactor

- HXCHEM

- China

- 70 days after payment

- 4 sets/month

Details

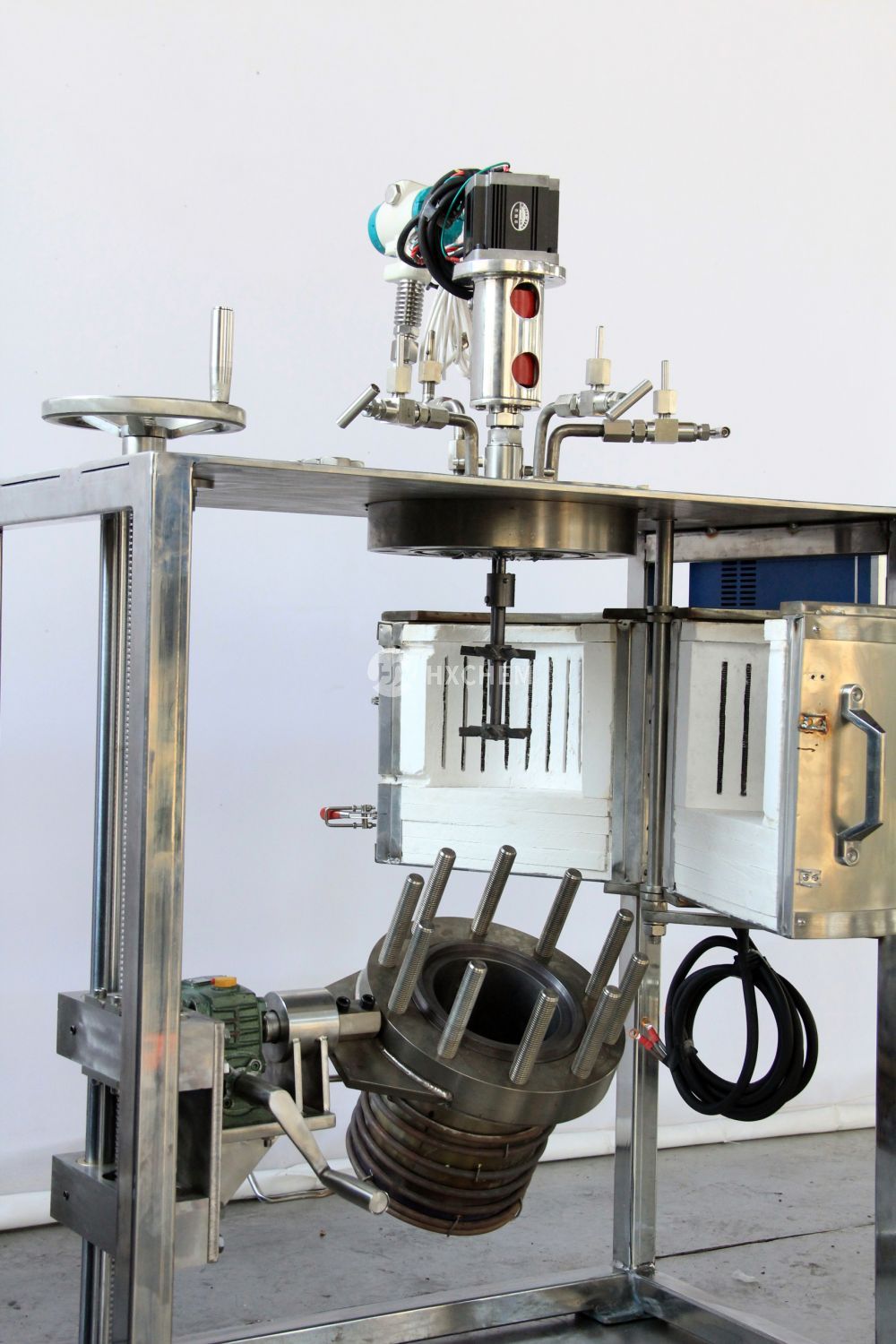

Lab stirred titanium reactor with tantalum liner

Lab high pressure reactors

Introduction

Voulume: 2lites, 3liters, 5liters

Maximum pressure: 100bar

Maximum temperature: 250C

MOC: Titanium with tantalum liner

Titanium (Reactor Body/Shell): Provides excellent structural strength, low density, good corrosion resistance to many chemicals (especially chlorides), and is relatively cost-effective for the main vessel.

Tantalum (Liner/Cladding): Acts as the ultimate barrier against corrosion. Tantalum is nearly inert to almost all acids (except hydrofluoric acid and hot, concentrated sulfuric acid) and has superb resistance to pitting and crevice corrosion.

Features

Flat cover lid: Fixed

Shaft seal: Magnetic coupling drive

Reactor vessel: Lifting & lowering & tilting.

Heating method: Electric heating with furnance detachable.

Cooling method: Spiral cooling coils set inside the furnance.

Standard specfications

GSH pressure reactor standard specification table.

| Model No. | GSH-0.1 | GSH-0.25 | GSH-0.5 | GSH-1 | GSH-2 | GSH-5 |

| Nominal Capacity | 100ml | 250ml | 500ml | 1liters | 2liters | 5liters |

| Max Working Pressure | Standard 100bar; Max pressure up to 350bar | |||||

| Working Temperature | Standard 350°C;Up to 500°C | |||||

| Stirring Speed | 0-1500rpm | |||||

| Motor Power | 150W | 150W | 150W | 0.2KW | 0.2KW | 0.6KW |

| Heating Power | 1KW | 1KW | 1KW | 2KW | 2KW | 4KW |

| Closure | Flange bolts closure/ Clamp closure | |||||

Lifting & lowering (Optional) | Cover lid lifting, Vessel fixed Cover lid manual lifting, Vessel rotation Vessel lifting & lowering, vessel rotation Manual; Electric driven; Pneumatic; Hydraulic (Driven method) | |||||

| Material | SS304,SS316 or other alloys(Titanium, tatanlum, hastelloy, Inconel, Nickel, etc) | |||||

| Heating Method | Standard Electric heating ( Jacket heating, far infrared heating optional ) | |||||

| Cooling | Internal spiral coils(optional) | |||||

| Charging Method | Up discharge by pressure or discharge by bottom valve | |||||

| Stirring type | Propeller, paddle type, turbine, anchor type, gas induction, helix type, etc. | |||||

| Control panel | Temp.display and control, accuracy+ 1℃, Stirring speed display & control Touch screen program control(Optional) | |||||

| Standard fittings | Pressure Gage, Thermocouple, Central stirring port Liquid inlet/ Sampling port with needle valve & dip tube and gas inlet with needle valve Safety Rupture Disc: Internal cooling Coil(Optional); Solid feeding plug(Optional) | |||||