Manual lifting and rotate laboratory pressure reactor

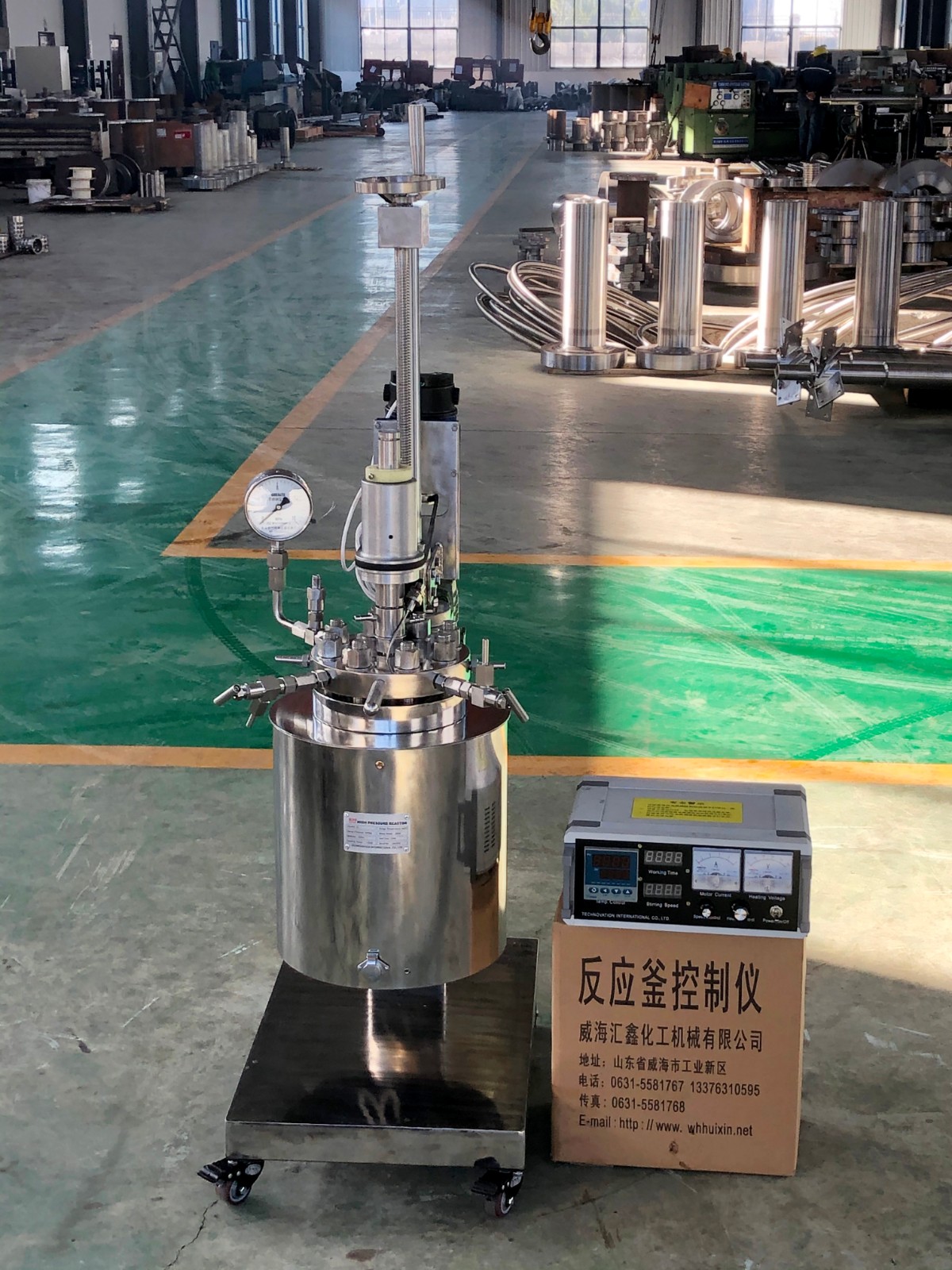

Manual lifting and rotate laboratory pressure reactor;SS316, ;100bar;350℃;Lift&flip device;Magnetic coupling drive Our pressure reactor could service wide range of industrial company, like environmental protection in petroleum, chemical industry, medicine, dyes, mining and metallurgy, scientific research institutes, colleges (chemical, polymer, material engineering, organic and inorganic chemical). Pressure range 0.1-50MPa, volume range 0.1L-50,000L. High pressure reactor vessel | high pressure autoclave reactor | lab mini autoclave reactor | Reaction autoclave

- HXCHEM

- China

- 45 days after payment

- 40 sets/month

Details

Manual lifting and rotate laboratory pressure reactor

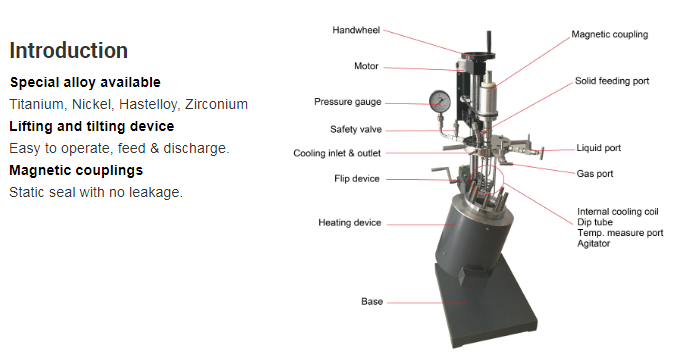

Introduction

This serious is equipped with lift and flip device, which makes it easier to discharge and clean the inner. Lifting device is easy to operate and use, turn the handwheel to lift square iron and kettle cover, rotate the kettle body to the right position by turning handle to discharge the material. The self-tuning function of the temperature controller makes the temperature control more precise.It is mainly used for lab or pilot experiment.

lab reactor homogenizer | lab scale reactor | small scale lab reactors | Lifting and rotate lab pressure reactors

Lab stirred autoclaves | Lab reactor system | High pressure laboratory reactor

2L pressure reactor standard specification

Model: GSHK-2

Volume: 2 liters

Material: SS316,

Maximum pressure: 100bar

Maximum temperature: 350℃

Inner diameter: 114mm, 240mm height

Heating method: Electric heating unite(1.5kW)

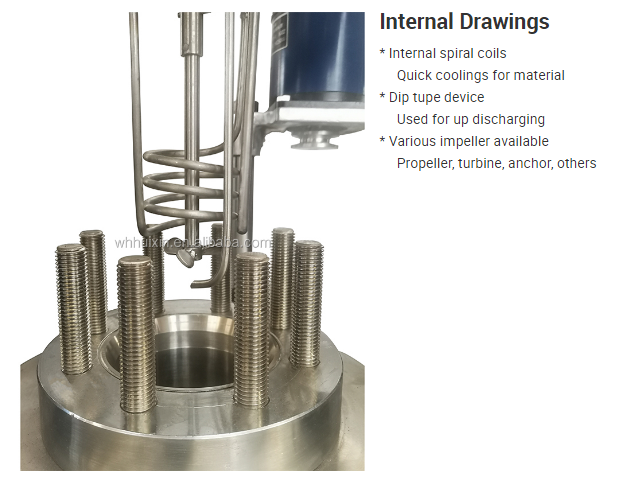

Cooling method: Internal cooling spiral coils

Stirring type: Top magnetic coupling drive ,0-1500rpm(150W)Propeller

Seal type:Hard sealing surface

Control system:PID control; Temp. & stirring speed display & control

Product Features

Standard specfications

GSH pressure reactor standard specification table.

| Model No. | GSH-0.1 | GSH-0.25 | GSH-0.5 | GSH-1 | GSH-2 | GSH-5 |

| Nominal Capacity | 100ml | 250ml | 500ml | 1liters | 2liters | 5liters |

| Max Working Pressure | Standard 100bar; Max pressure up to 350bar | |||||

| Working Temperature | Standard 350°C;Up to 500°C | |||||

| Stirring Speed | 0-1500rpm | |||||

| Motor Power | 150W | 150W | 150W | 0.2KW | 0.2KW | 0.6KW |

| Heating Power | 1KW | 1KW | 1KW | 2KW | 2KW | 4KW |

| Closure | Flange bolts closure/ Clamp closure | |||||

Lifting & lowering (Optional) | Cover lid lifting, Vessel fixed Cover lid manual lifting, Vessel rotation Vessel lifting & lowering, vessel rotation Manual; Electric driven; Pneumatic; Hydraulic (Driven method) | |||||

| Material | SS304,SS316 or other alloys(Titanium, hastelloy, Inconel, Nickel, etc) | |||||

| Heating Method | Standard Electric heating ( Jacket heating, far infrared heating optional ) | |||||

| Cooling | Internal spiral coils(optional) | |||||

| Charging Method | Up discharge by pressure or discharge by bottom valve | |||||

| Stirring type | Propeller, paddle type, turbine, anchor type, gas induction, helix type, etc. | |||||

| Control panel | Temp.display and control, accuracy+ 1℃, Stirring speed display & control Touch screen program control(Optional) | |||||

| Standard fittings | Pressure Gage, Thermocouple, Central stirring port Liquid inlet/ Sampling port with needle valve & dip tube and gas inlet with needle valve Safety Rupture Disc: Internal cooling Coil(Optional); Solid feeding plug(Optional) | |||||

Typical Applications