laboratory wiped film evaporation units

Lab wiped film evapoation and thin film evaporators consist of a cylindrical heating jacket and an inner rotating wiper system, distributing the product on the heating jacket as a thin and turbulent film. The turbulence in the wiped film increases the heat and mass transfer to achieve a high evaporation rate at short residence times, often within a single processing pass. The separated vapors are either condensed on an external condenser or further separated in a fractional column. Wiped film and thin film evaporation allow the handling of heat-sensitive, fouling and viscous products.

- HXCHEM

- China

- 50 days after payment

- 15 sets/month

Details

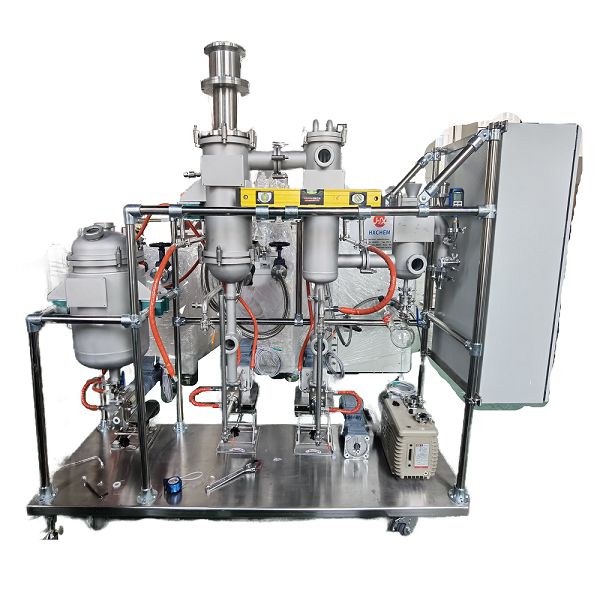

Laboratory thin film distillation/ wiped film evaporation units

Introduction

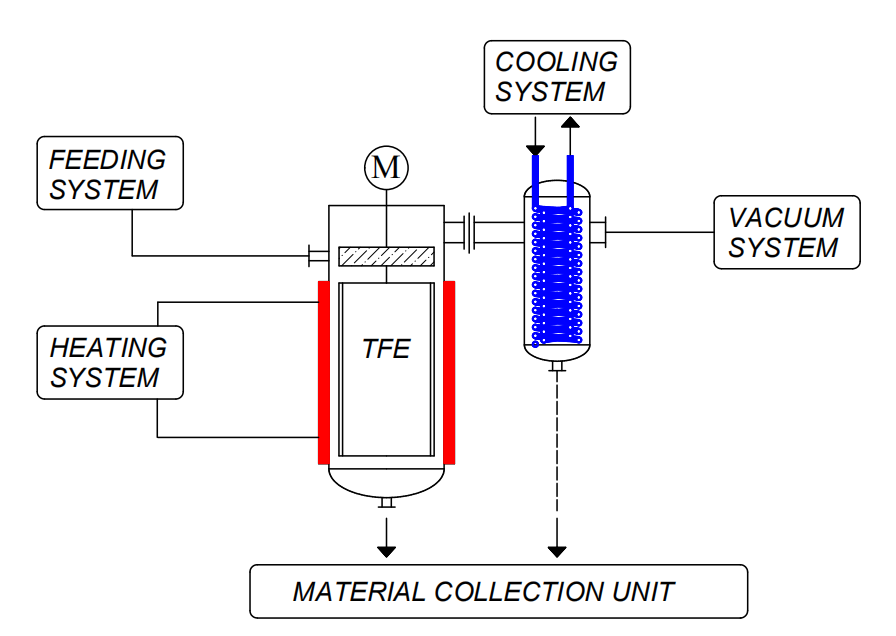

In a lab thin film evaporator(TFE), a rotating wiper system distributes the crude product to a film on the inner surface of a heated surface. The wiping system speeds up the evaporation process by keeping the product film turbulent so that the heat transfer and mass transfer are optimized. The vapour are condensed on the external condenser and the residue are discharged from the bottom of the evaporator.

1. This system is a pilot type single stage thin film evaporation device. The main evaporator material is stainless steel;

2. The device is designed with a jacket heating system, with thermal oil circulation heating, and a maximum temperature of 300 ℃. The feeding and recombining discharge system (including sight glass, gear pumps, and discharge siphons) is designed with a jacket, which can handle high viscosity materials.

3. The device adopts three gear pumps for feeding and separating light and heavy materials. The gear pumps can directly transport materials from high vacuum to atmospheric pressure, and can achieve continuous distillation production without stopping for 24 hours, conveying high viscosity materials (at an operating temperature of 20000 cp);

Evaporation area | : | 0.15 m2 |

Processing capacity | : | 2-12kg/h |

Evaporation temperature | : | 30-350℃ |

Minimum vacuum degree without load | : | 5 Pa |

Minimum vacuum degree during operation (after feeding) | : | 100Pa |

Maximum viscosity of materials that can be processed | : | 20000mPas@during operation temperature |

Product Features

High heat transfer efficiency, fast evaporation speed and short material residence time.

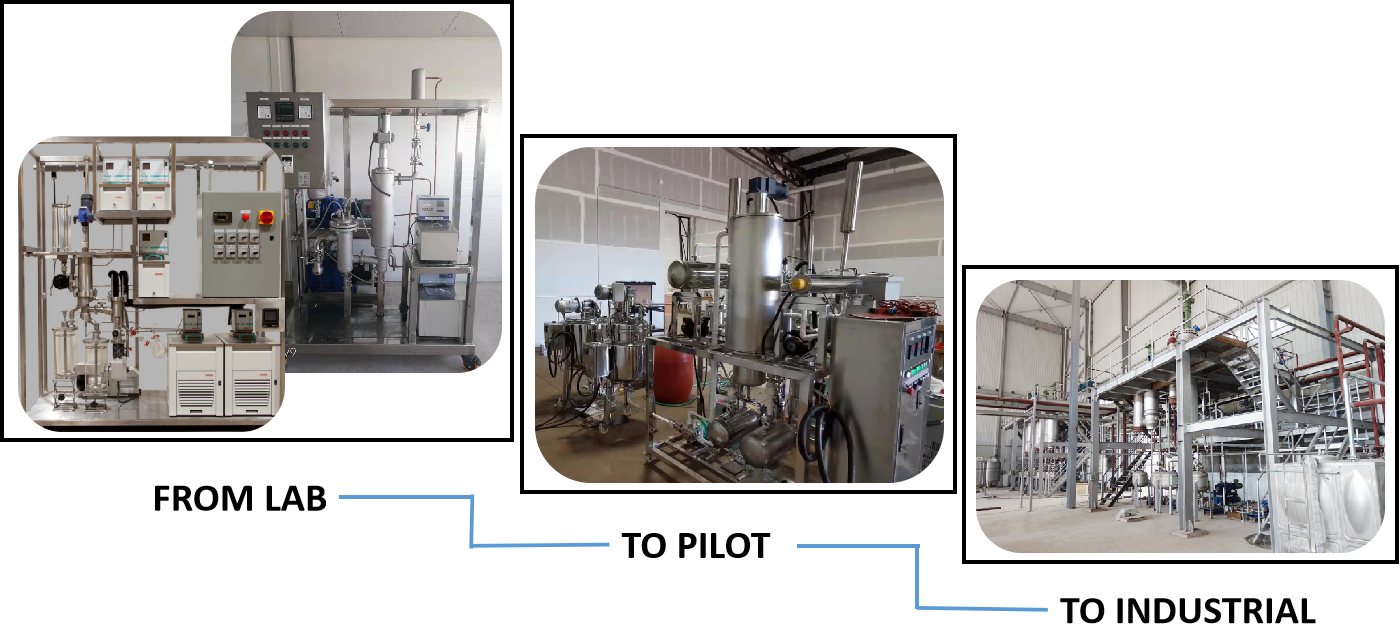

Heating area: 0.05m2, 0.1m2, 0.3m2, 0.5m2 available.

Batch or Continuous distillation process available.

Combination with additional evaporation stages (Rectification Column, Degassing stage, etc)

TFD constructed of borosilicate glass, stainless steel or other special materials and alloys.

Different wiper systems are selected depending on the product properties.

Gear automatic discharge pump

Basic Configuration(TFD)

Feeding system(including pre-heating and degassing stage)

Thin film evaporator(TFE)

External condenser and cold trap

Collection systems for distillate and residue

Heating and cooling systems

Vacuum system

Application

Laboratory wiped film evaporation units; Lab thin film distillation; Laboratory wiped film evaporation system; Laboratory thin film distillation; laboratory wiped film distillation; Lab wiped film evapoation; Lab thin film evapoation; Lab wiped film distillation; Lab thin film distillation; Wiped film evaporation units; Laboratory wiped film evapoation; Our process solutions are used for purification, concentration, removal of low boilers, colour improvement, drying of products and much more. Oils, fats and food; Chemical, agro chemical and pharamaceutical products; Petrochemical products; Polymers; Fragrances and flavors; Recycled materials.