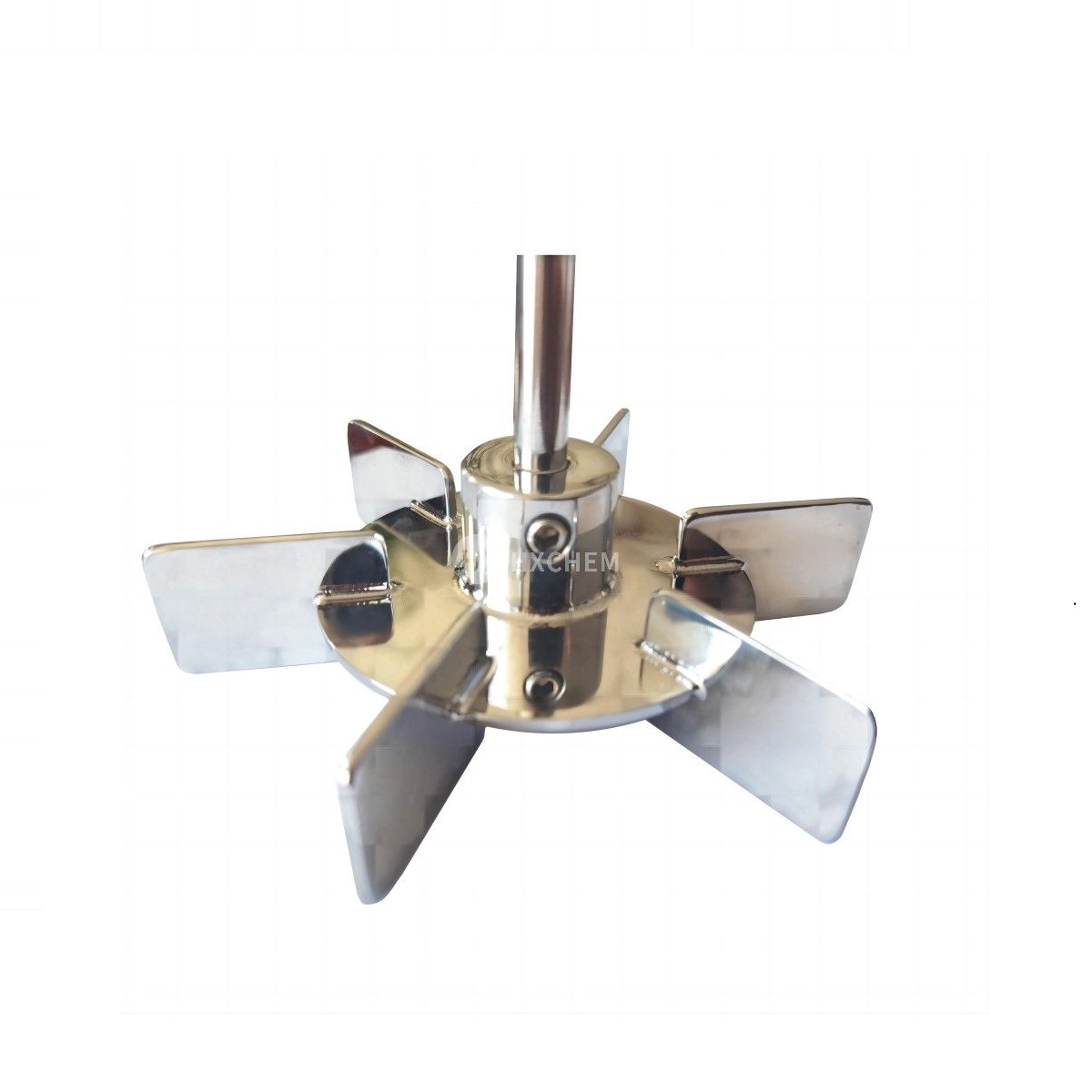

45 degree Pitched Blade Turbine

45° Pitched Blade Turbine (PBT) is a type of axial-flow impeller where the blades are set at a 45-degree angle relative to the plane of rotation. This specific angle is a standard design that creates a strong, downward-pumping axial flow pattern, making it one of the most versatile and commonly used impellers for a wide range of mixing applications.

- HXCHEM

- China

- 10 days after payment

- 30 sets/month

Details

45 degree Pitched Blade Turbine

Introduction

A 45° Pitched Blade Turbine/ Stainless steel Pitched Blade Turbine is a type of axial-flow impeller where the blades are set at a 45-degree angle relative to the plane of rotation. This specific angle is a standard design that creates a strong, downward-pumping axial flow pattern, making it one of the most versatile and commonly used impellers for a wide range of mixing applications.

Technical Requirements

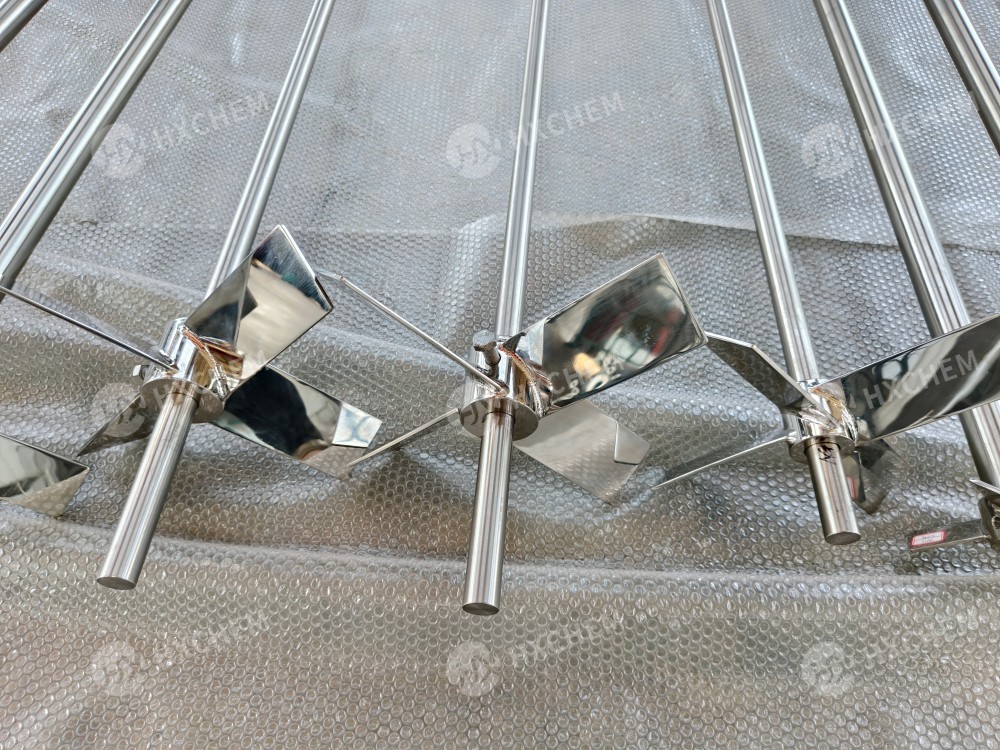

Diameter of impeller(mm): 50, 80, 90, 100, 120, 150, 200, 250, 300, 400, 500, 600,800, 1000, etc.

Shaft hole(mm): 8mm, 10mm, 12mm, 18mm, 25mm, 30mm, 40mm, 50mm, etc.

Quantity of blade: 4 blades or 6 blades

Blade angle: Fixed at 45 degrees (though some designs vary slightly, e.g., 30°-60°).

Flow pattern: Axial Flow (Down-pumping). The primary flow is parallel to the impeller shaft, pushing fluid downward toward the tank bottom.

Blade thickness: 3mm, 4mm, 5mm, etc

Material: SS304, SS316L, Hastelloy C276, Titanium

Product Details

Advantages

Versatility: Excellent for a wide array of tasks: blending, solid suspension, heat transfer, and some gas dispersion.

Good Solids Suspension: The strong downward axial flow is very effective at lifting and keeping solids off the tank bottom (e.g., in crystallization or leaching processes).

Efficient Blending: Creates strong top-to-bottom motion, making it efficient for achieving homogeneity in low to medium viscosity fluids.

Cost-Effective: Simple, robust design makes it relatively inexpensive to manufacture and maintain.