Electromagnetic induction heating chemical reactor

Electromagnetic induction heating/ Electromagnetic induction reactors/ Electromagnetic induction heating reactor/ Induction heating reactor/ Electric heating chemical reactor Induction heating chemical reactors, Induction heating pressure autoclaves, Induction heating Vessels, Induction heating storage tanks, Induction heating pressure vessels,Induction heating resin reactors

- HXCHEM

- CHINA

- 90 days after payment

- 10 SETS PER MONTH

Details

Electromagnetic induction chemical reactor

Introduction

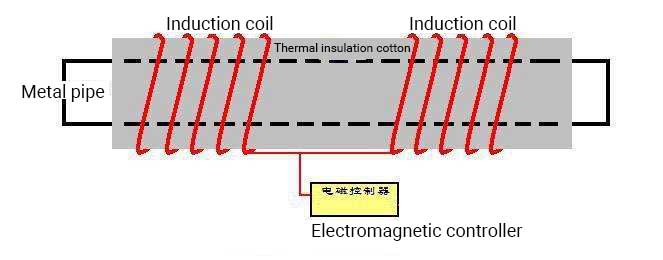

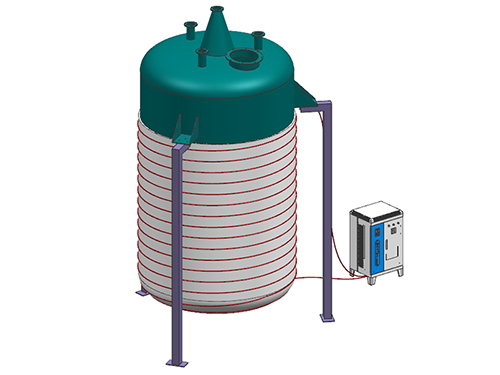

Induction heater usually referred as Electromagnetic induction heating power supply. Induction heating coil designs are available to suit metallic vessels and tanks of most forms and shapes in current use. Mild steel, clad mild steel, solid stainless steel or non ferrous vessels can all be successfully heated. Generally a minimum wall thickness of 6mm is recommended.

As each induction heating vessel is bespoke to each customers specific needs and requirements, we offer varying sizes with differing heat up rates. Our engineers have had many years of experience in evolving custom built induction heating systems for a wide range of applications in a wide range of industries. Heaters are designed to suit the precise requirements of the process and are constructed for quick fitting onto the vessel either in our works or on site.

Features

• No physical contact between induction coil and heated vessel wall.

• Rapid start-up and shut-down. No thermal inertia.

• Low heat loss

• Precision product and vessel wall temperature control without over shoot.

• High energy input. Ideal for automatic or micro-processor control

• Safe hazard area or standard industrial operation at line voltage.

• Pollution free uniform heating at high efficiency.

• Low running costs.

• Low or high temperature working.

• Simple and flexible to operate.

• Minimum maintenance.

• Consistent product quality.

• Heater self-contained on vessel generating minimum floor space requirement.

Reactor/ Kettle/ Vessel volume: 100L---20000L

Material:Carbon steel,Stainless steel

Applications

√ It offers a widely range of applications for industrial heating in the Plastics, Chemical, Pharmaceutical, Food, Printing, Construction, HVAC, Heat Treatment, Smelting And Other Industries Energy Saving. for example: plastic inject molding machine, oil heating, hot water, metal heating, hot air, diffusion pumps heating and other custom applications.

What’s Induction Heating?

Electromagnetic induction heating, or electromagnetic heating (Electromagnetic Induction Heating abbreviation: IH) technology, is the principle of electromagnetic heating through the composition of the electronic circuit board to produce an alternating magnetic field, when an iron containing container is placed on it, the surface of the container is cut alternating magnetic force line and produces alternating current at the bottom of the container. Eddy current makes the carrier at high speed move irregularly at the bottom of the container, and the carriers collide with each other and produce heat. So that the effect of heating items. Because the iron container is self heating, the thermal conversion rate is particularly high, up to 95%, which is a direct heating method.

The Electromagnetic Induction Heating System Is Composed Of An Electromagnetic Heating Controller(induction heater) And An Electromagnetic Heating Coil.