ASME pressure vessels

HXCHEM have ASME U stamp certificate, and specialize in ASME pressure vessels; ASME stamp pressure vessels;ASME standard pressure vessels; ASME code pressure vessels

- HXCHEM

- CHINA

- 60 days after payment

- 15sets/ month

Details

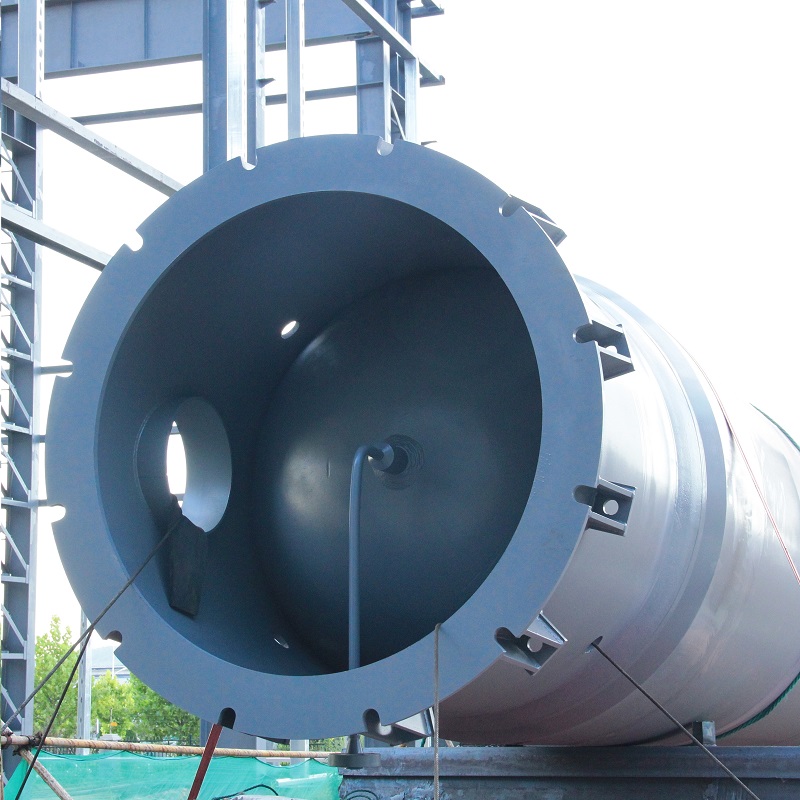

ASME pressure vessels

HXCHEM is an ASME code vessel shop and carries a Certificate of Authorization to fabricate pressure vessels to ASME Section VIII, Div. We offer extensive expertise in the mechanical design of ASME pressure vessels that will meet rigorous quality standards and procedures and are guaranteed for a long, trouble-free vessel life.

INTRODUCTION

This serie product is applicated in the gas storage, which is under the high pressure enviroment. The vessels are strong and durable and can be designed to be abrasion resistant, corrosion resistant or with alternate metallic liners for added strength.

FEATURES

Mild steel ASME certified pressure vessel manufacturers / ASME stamp pressure vessels

* Volume: 50lires---80kl;

* Max pressure: 200 bar;

* Vertical and horizontal gas storage tanks, liquid storage, and vacuum tanks, etc.

* The medium is air, hydrogen, nitrogen, oxygen, natural gas, water, liquefied gas, oil, refrigerant, etc.

* The product meets the requirements of various standard code such as ASME, PED, GB150.

* Material: Carbon steel SA516 Gr70; SS316L; Titanium; Hastelloy C276 cladding, etc.

* When the pressure is large, cladding plates could be considered, including base material for strength and clad material for anti-corrosion. Reduce costs for you!

At alloy engineering, we have the expertise to customize pressure vessels to your specifications. We can assist with critical issues such as material selection and design optimization. We also offer specialized design and welding techniques for these demanding high temperature and corrosive Applications.

Customization

Our custom pressure vessels are designed and fabricated to an array of considerations, including:

Size / Volume

Horizontal / Vertical orientation

Exotic Materials and Alloys

High Design Pressures

High Design Temperatures

Jackets, including Half Pipe, Dimple or Conventional

Internal heating / cooling coils

Accessories

HXCHEM has fabricated a number of unique vessels over the decades.

Give us the opportunity to meet your requirements and we’re sure you’ll be more than satisfied. Contact us today to discuss your custom pressure vessel needs!

CYLINDRICAL PRESSURE VESSELS

Cylindrical pressure vessels are the most commonly used vessels for storage of high pressure gasses and fluids. The “shell” of a pressure vessel refers to its wall, which is typically cylindrical. The shell is composed of metal plates with a thickness carefully calculated to sufficiently contain the pressure of the vessel’s contents.

NON- FERROUS METAL CLADDING

These metal plates are typically made to withstand pressure, as well as the specific types of corrosion commonly caused by the materials it is intended to contain. Materials used for pressure vessel shells include but not limited to: Stainless steel, Duplex steel, Titanium alloy, Hastelloy, Inconel, Monel Alloy, etc.

PRESSURE VESSEL HEADS

Flat / Torispherical heads / Elliptical heads / Conical heads.

HEAT TRANSFER

Half pipe coil jacket:Half-pipe coil jackets consist of metal shaped into concentric circles or coils and welded to the exterior of the container. They are useful for rapid heating or cooling of the contents of the container and are stronger than mechanical dimpled jackets.

Conventional jacket:The conventional jacket is a cover over all or part of the vessel with an annular space between the outer vessel wall and the inner jacket wall, generally concentric. This is the most popular jacket.

USES OF PRESSURE VESSELS

Pressure vessels are useful for a wide range of applications, including:

Jacketed Reactors

Storage Tanks

Chemical Reactors

Mixing Vessels

Distillation Towers

Autoclaves

Heat Exchangers

Vacuum Tanks

Common locations where pressure vessels may be found include Pharmaceutical, Cosmetic, Chemical, food processing and dairy processing facilities.

Pressure vessels are composed of a shell, head, and supports, with additional attachments as needed for the vessel’s particular application. Each component of a pressure vessel will have a different design and composition based on its intended use.