1m2 wiped film short path molecular distillation

1m2 wiped film short path molecular distillation; laboratory scale stainless steel wiped film molecular distillation, lab scale short path molecular distillation, thin film distillation.

- HXCHEM

- China

- 50 days after payment

- 20sets/month

Details

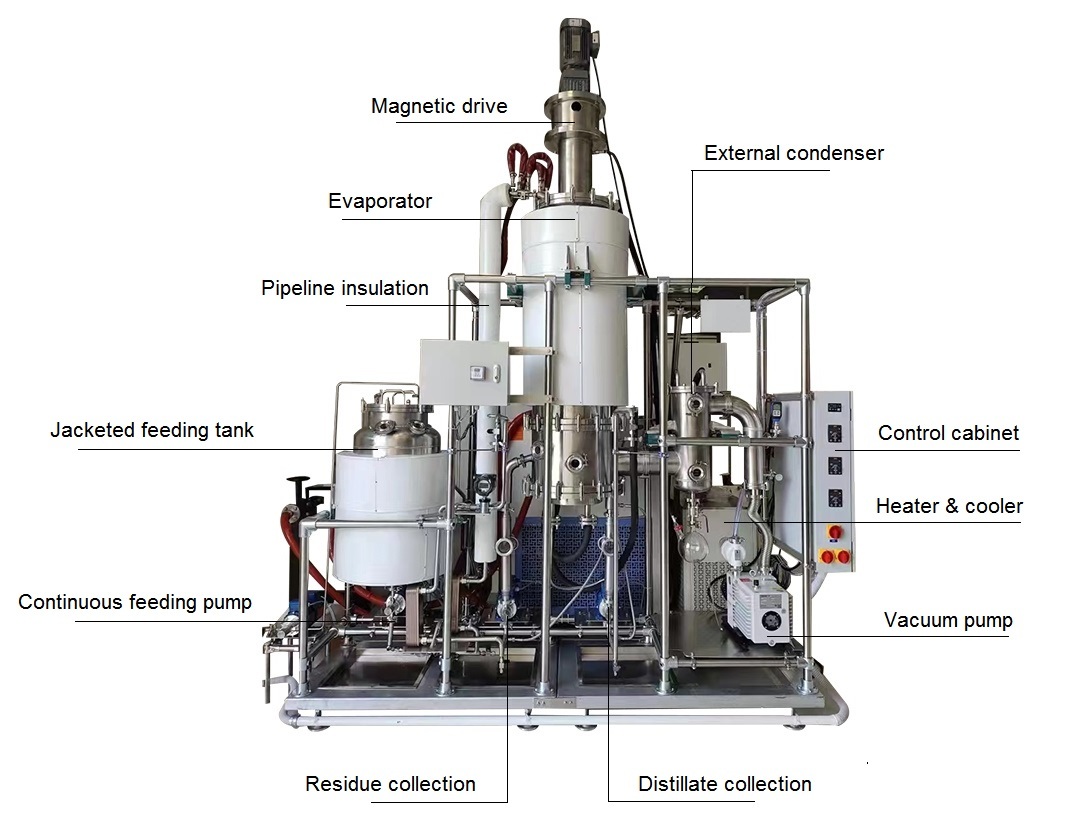

1m2 wiped film short path molecular distillation

Model: SPD-1-2022

Heating area: 1m2 .

Feed capacity:20-100kg/h

Distillation temperature:30-280℃

Tracing pipeline temp.: 180℃

Max. viscosity:1000mPas@Operate temperature

Vacuum:0.05mba

Power supply:380V (3L, 1N, 1PE) 50 Hz, 25kW

SPE constructed of SUS316.

The short path distillation plant with internal condenser, the raw material is distilled in a very short time by thin film with high vacuum condition. Suitable for distillation of high boiling point and heat sensitive material.

* High heat transfer efficiency, fast evaporation speed and short material residence time.

* Short evaporating distance with little pressure loss

Features

* High heat transfer efficiency, fast evaporation speed and short material residence time.

* Short evaporating distance with little pressure loss.

* Continuous or batch distillation process available, don't need to break vacuum.

* Trace heating of individual sections (Feed, residue and distillate) .

* Magnetic coupling drive for maintaining high vacuum degrees.

* The chilling units for the external condenser and cold trap.

* Floor stand or moveable cart design.

Basic Configuration

* Feeding system(Pipe with Double Insulating Jacket)

* Multi-stage short path evaporator(SPE)

* Cold trap/ Horizontal condenser

* Collection systems for distillate and residue

* Heating and cooling systems

* Vacuum system

Parameters

Heating surface | 1 m2 |

Internal condenser surface | 2m2 (Row Tubes wiper) |

Feed rate | 20-100 kg/h |

Distillation temperature | 30-280℃ |

Tracing temperature | 180℃ |

Vacuum | 0.05mba |

Max. viscosity of material | 1000mPas@Operate temperature |

Power supply | 380V (3L, 1N, 1PE) 50 Hz, 25kW |

Utilities on site | Water cycling |

Size of plant | 4.0m*3m*3.8m |

Wet material | SS.316L |

Roller wiper | PTFE with fiberglass |

Vacuum piping | SS.304 |

Frame of plant | Galvanized Carbon Steel |

Wet material gasket | FEP\FKM O-ring and PTFE,corrosion resistance |

Shaft sealing | Shaft sealing |

Application

Hemp industrialHemp oil (Full Spectrum, Broad Spectrum, Isolate ) Food productsMonoglycerides; Palm Oil; Fish Oil; Omega-3 FFA; Fatty Acids;Herb extracts; Sterols PharmaceuticalsPharma intermediates(API); Vitamin E; Glucose Derivatives; Terpene Esters; Beta-carotene ChemicalsAlcohols; Glycol Ethers; Herbicides; Halogenated Hydrocarbons; Insecticides; Silicon OilsTall-tan Oil; Waxes PlasticsAcrylics; Epoxy Resins; Deoxidized Oils; Isocyanates; Phenolics; Plasticizers; PolyethyleneStabilizers; Thermoplastic & Thermosetting Resins. Mineral oilsBase Oil; Lube Oils; Paraffinic Oils; Tar CosmeticsWool fatty Acids; Wool Alcohols; Extracts from Algae, Flowers, Roots, Capsicum