Lab pressure reactor customization

2025-02-27

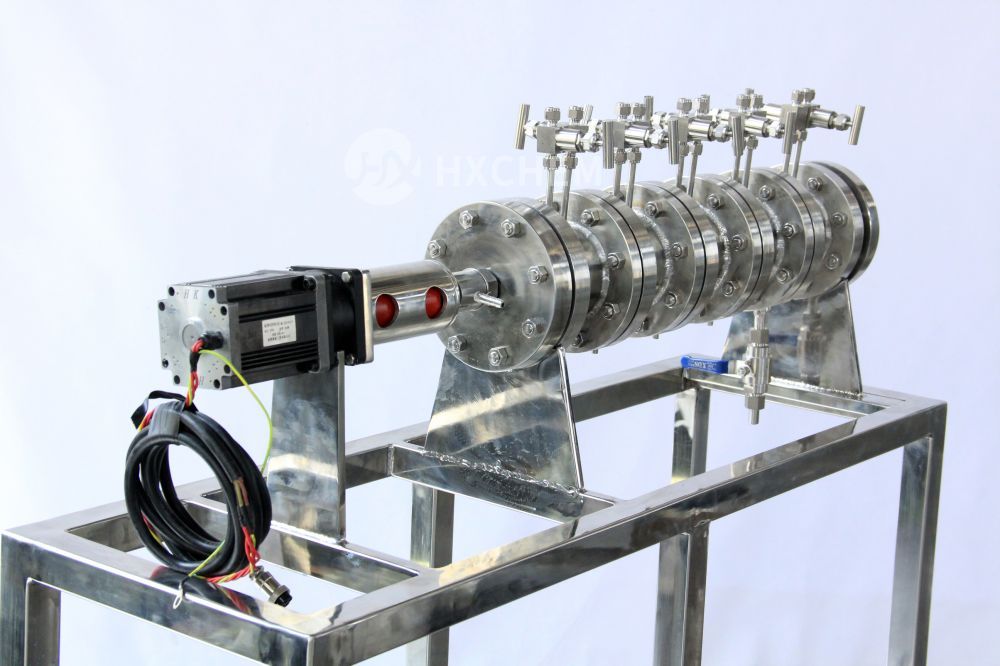

LAB PRESSURE REACTOR CUSTOMIZATION

Customizing a lab pressure reactor involves tailoring the design, materials, and features to meet specific experimental or production requirements. Pressure reactors are used for high-pressure and high-temperature reactions, such as hydrogenation, polymerization, and catalytic processes. Customization ensures the reactor is optimized for safety, efficiency, and performance. Below are key considerations and steps for customizing a lab pressure reactor:

1. Define Your Requirements

Reaction Type: Identify the type of reaction (e.g., hydrogenation, oxidation, polymerization).

Pressure and Temperature Range: Determine the maximum pressure and temperature needed.

Volume Capacity: Choose the reactor size based on the scale of your experiments (e.g., 100 mL, 1 L, 5 L).

Compatibility: Ensure the reactor is compatible with the chemicals, solvents, and catalysts used.

2. Material Selection

Stainless Steel (SS316/SS304): Common for most applications due to its corrosion resistance and durability.

Hastelloy or Inconel: For highly corrosive environments or extreme conditions.

Glass-Lined Reactors: For reactions requiring visibility or resistance to certain chemicals.

Teflon or PTFE Linings: For acidic or alkaline reactions.

3. Design Features

Pressure Rating: Customize the reactor to handle specific pressure ranges (e.g., 100 psi, 1000 psi, or higher).

Temperature Control: Include heating/cooling options like:

Jacketed systems for external heating/cooling.

Internal coils for direct temperature control.

Agitation System:

Magnetic stirrers for small-scale reactors.

Mechanical stirrers with adjustable speed for larger reactors.

Ports and Connections:

Multiple ports for adding reagents, sampling, or attaching sensors.

Gas inlet/outlet valves for reactions involving gases (e.g., hydrogen, nitrogen).

Safety Features:

Pressure relief valves.

Rupture disks for overpressure protection.

Temperature and pressure sensors with alarms.

4. Instrumentation and Automation

Sensors: Include pressure transducers, thermocouples, and pH probes for real-time monitoring.

Control Systems: Integrate programmable logic controllers (PLCs) or software for automated control of temperature, pressure, and stirring.

Data Logging: Add data acquisition systems to record and analyze reaction parameters.

5. Additional Customization Options

Scale-Up Features: Design the reactor to allow easy scaling from lab to pilot or production scale.

Modular Design: Include interchangeable parts for flexibility in different experiments.

Specialized Coatings: Apply anti-corrosion or non-stick coatings for specific reactions.

Transparent Windows: Add sight glasses or quartz windows for visual monitoring.

6. Safety Considerations

Ensure the reactor meets industry standards (e.g., ASME, PED).

Include fail-safe mechanisms for pressure and temperature control.

Provide training for operators on safe handling and emergency procedures.

7. Work with a Manufacturer

Collaborate with a reputable manufacturer or supplier specializing in lab pressure reactors.

Provide detailed specifications and discuss your application needs.

Request a prototype or simulation if necessary.

Example Customization Scenario

Application: Hydrogenation of organic compounds at 200°C and 500 psi.

Customization:

Material: Hastelloy C-276 for corrosion resistance.

Volume: 2 L capacity.

Features: Jacketed heating, magnetic stirring, gas inlet for hydrogen, pressure relief valve, and data logging.

Safety: Rupture disk and automated pressure control.

By customizing a lab pressure reactor, you can achieve precise control over reaction conditions, improve efficiency, and ensure safety. Always consult with experts to design a reactor that meets your specific needs.