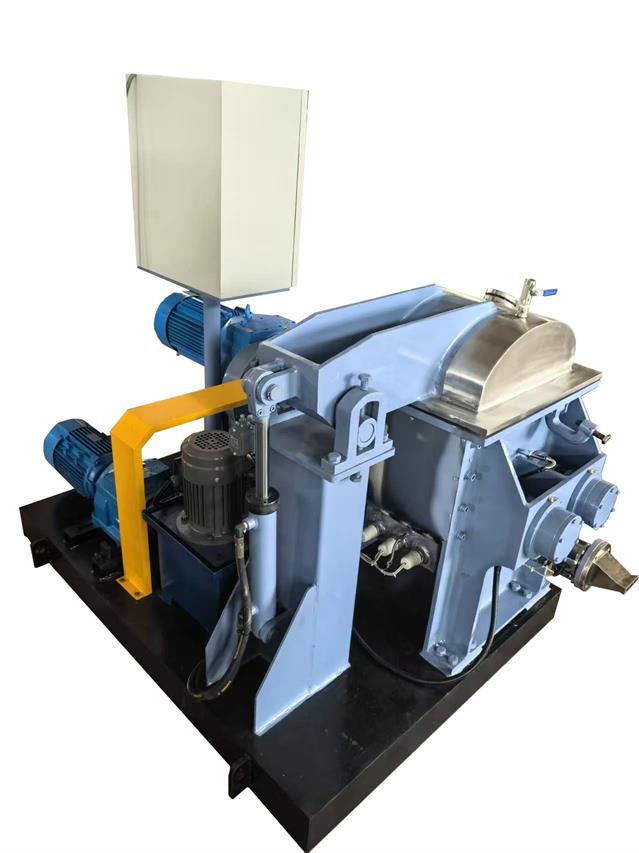

Introducing the Advanced 200L Non-Stick Paste Mixer: Precision Mixing for Demanding Applications

2025-06-13

Introducing the Advanced 200L Non-Stick Paste Mixer: Precision Mixing for Demanding Applications

[HXCHEM] –proudly unveils its state-of-the-art 200L Non-Stick Paste Mixer, engineered to deliver exceptional performance, reliability, and control for high-viscosity mixing processes in industries such as adhesives, sealants, chemicals, pharmaceuticals, and advanced materials.

Designed for efficiency and durability, this robust Z-blade mixer features a comprehensive suite of advanced specifications and automation capabilities, ensuring consistent, high-quality results even with the most challenging non-stick pastes.

Core Specifications & Features:

Mixer Type & Structure:

Non-Stick Paste Mixer with heavy-duty Z-shaped Blades and Spiral Discharge Auger.

Frame Support Structure for stable installation.

All-Metal Z-Blades & Discharge Auger: Ensures strength and longevity under heavy loads.

Capacity & Construction:

Total Volume: ≥ 0.16 m³

Operating Volume: 0.1 m³ (200L)

Contact Area: Constructed from high-grade SS304 Stainless Steel for excellent corrosion resistance and product purity.

Viewing Window: Integrated Glass Viewing Window on the cover for process monitoring.

Performance & Control:

Rotation Speed (Blades & Auger): Variable speed from 0 to 100 RPM, controlled via frequency converters.

Reversible Operation: Both the Z-blades and the discharge auger feature reversible movement for enhanced mixing flexibility and efficient product evacuation.

Temperature Control:

Operating Temperature: ≥ 200°C

Jacket Pressure: ≥ 0.6 MPa

Heating Power: 6 - 8 kW heating element within the jacket.

Control Module: Provides two-point temperature indication and regulation (jacket and inner body).

Pressure Monitoring: Pressure indication (gauge) for the mixing chamber.

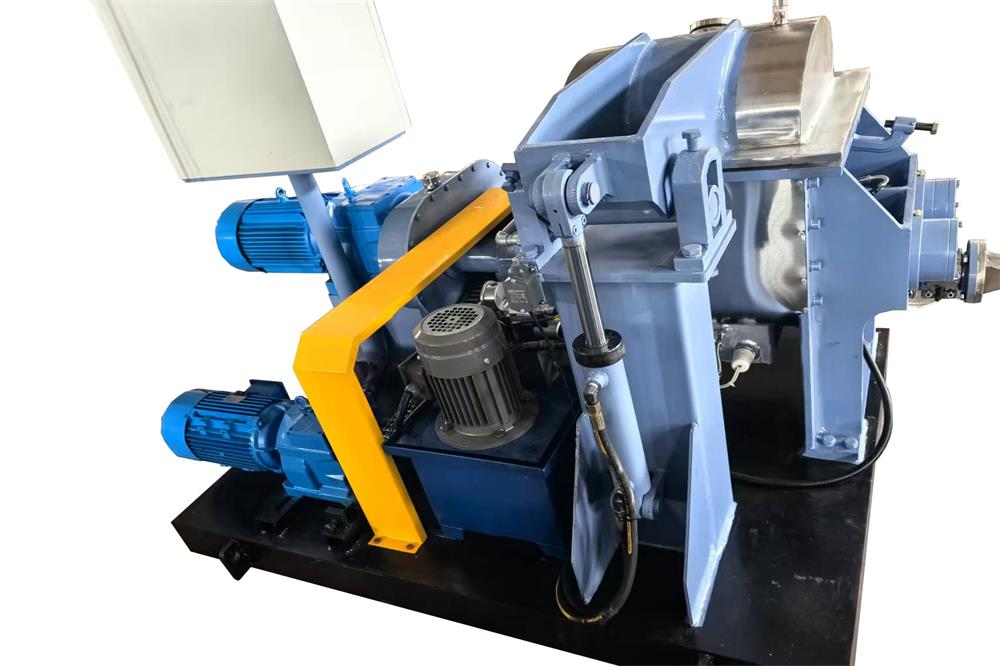

Drive System:

Rotor Motor: 7.5 kW, frequency controlled.

Discharge Auger Motor: 3 kW, frequency controlled.

Direct Drive Transmission via half coupling between motor and gearbox.

Critical Engineering & Safety:

Sealing: Gland seals made of durable fluoroplastic cord on all shafts for reliable containment.

Bearing Support: Robust bearings provided on both sides of the discharge shaft, plus an additional support on the unloading side of the auger shaft for maximum stability and reduced shaft deflection.

Explosion Safety: Features an Explosion-Proof Electric Drive (motors).

Control Cabinet: Standard control cabinet (non-explosion proof - specify if optional Ex available).

Automation & Documentation:

Integrated Control Unit: Full automation capability via the dedicated mixer control module.

Comprehensive Documentation: Supplied with a minimum set of technical documentation including Passport, design documentation, drawings, and component passports/certificates.

Designed for Excellence:

This 200L mixer is built to handle demanding mixing tasks efficiently and safely. The combination of powerful Z-blade mixing, precise temperature and speed control, robust construction (SS304), explosion-proof drive, and the convenience of the reversible spiral discharge auger makes it an ideal solution for manufacturers requiring high-quality, repeatable mixing of viscous, non-stick pastes and compounds.

Power & Connection:

Connection Voltage: 380V

Total Installed Power: 17 kW (7.5kW Rotor + 3kW Auger + 6-8kW Heating)

Discover the Difference:

Elevate your production capabilities with the reliability and advanced features of the [HXCHEM] 200L Non-Stick Paste Mixer. Contact us today for a detailed quotation or to discuss how this mixer can optimize your specific application.