PTFE Lined Lab Pressure Reactor With Lifting Lowering functions

Floor stands or moveable cart type. Laboratory autoclaves with 500 ml to 5 liters volume. Max pressure: 300 bar; Max temperature up to 200 ℃ High pressure reactor vessel | Low to high torque magnetic couplings: static seal with no leakage. Available material:SS304, SS316, Titanium, Nickel, Hastelloy B/C, Monel, Zirconium, Inconel, Tantalum. Lifting device for easy operation,low labor cost. Monitor and control: Temperature, pressure, motor speed, gas / liquid flow, level, etc Safety Device (Blasting Disc) on Security Blasting Port. Customized according to customers requirement.

- HXCHEM

- China

- 10 days after payment

- 30 sets/month

Details

PTFE Lined lab Reactor with Lifting Lowering Mechanism

Introduction

A kind of PTFE lined reactor with lifting device, which can resist acid, alkali and corrosion of various organic solvents, easy to operation and cleaning because of lifting mechanism. This reactor can widely used for various test and reaction in laboratory, under high pressure, high vacuum and high temperature condition. And sometimes it can be equipped with external condenser for distillation and vapor collection.

Lifting high pressure reactors | PTFE lined reactor | Lab hydrogenation reactor

Lab reactor cost | Heating reactor lab | Jacketed lab reactors

Product Features

? Floor stands or moveable cart type.

? Laboratory autoclaves with 500 ml to 5 liters volume.

? Max pressure: 300 bar; Max temperature up to 200 ℃

? Low to high torque magnetic couplings: static seal with no leakage.

? Available material:SS304, SS316, Titanium, Nickel, Hastelloy B/C, Monel, Zirconium, Inconel, Tantalum.

? Lifting device for easy operation,low labor cost.

? Monitor and control: Temperature, pressure, motor speed, gas / liquid flow, level, etc

? Safety Device (Blasting Disc) on Security Blasting Port.

? Customized according to customers requirement.

Specifications

Model No. | GSH-0.5 | GSH-1 | GSH-2 | GSH-3 | GSH-5 |

Nominal Capacity (L) | 0.5 | 1 | 2 | 3 | 5 |

Working Pressure (MPa) | 10 | 10 | 10 | 10 | 10 |

Working Temperature(℃) | 200 | 200 | 200 | 200 | 200 |

Stirring Speed (r/min) | 0-1500 | 0-1500 | 0-1500 | 0-1500 | 0-1500 |

Motor power (kW) | 0.15 | 0.2 | 0.2 | 0.2 | 0.6 |

Heating Power (kW) | 1 | 2 | 2 | 3 | 4 |

Heating Method | General electric heating(water recycling, thermal oil heating available) | ||||

| Cooling Method | Spiral coils(Single coils, serpentine coils available) | ||||

| Charging Method | Charging from above | ||||

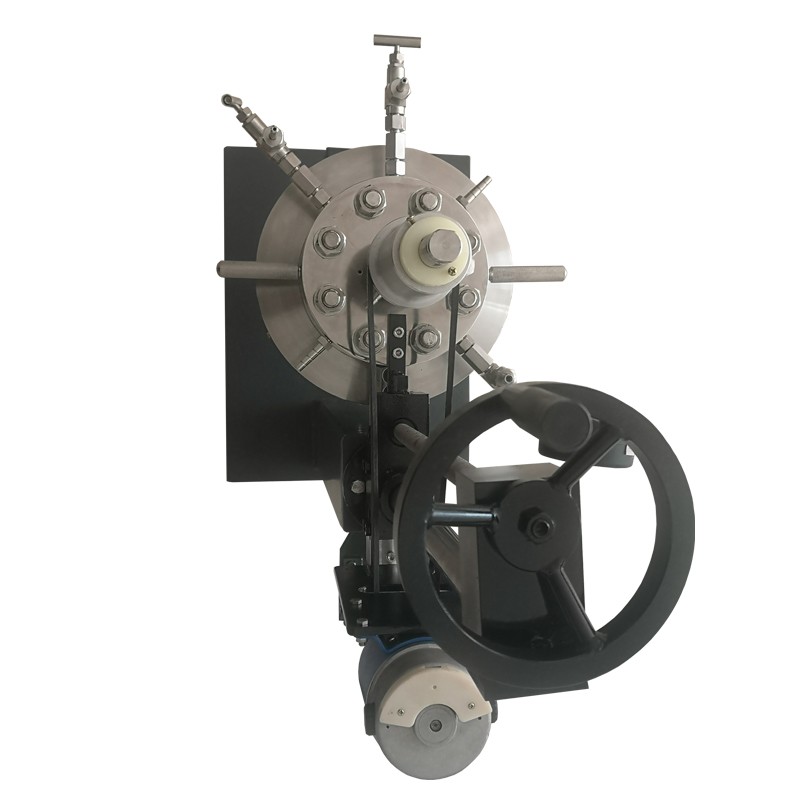

| Lifting type | Mannual operation | ||||

| Stirring type | Propeller, paddle type, anchor type or customized | ||||

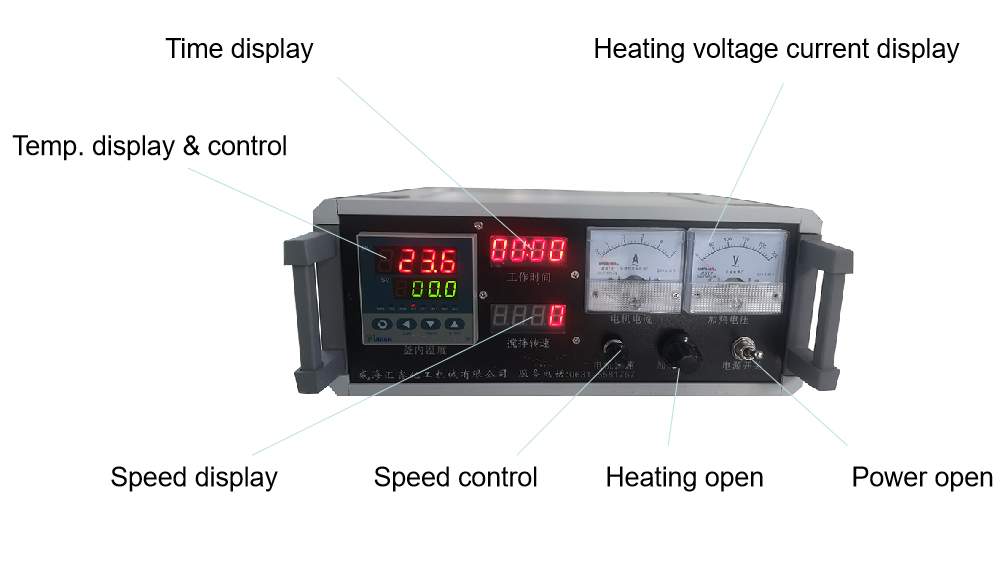

Control panel | Temperature, time and heating voltage display Temperature adjustment control, accuracy±1 ℃ Stirring speed display and control | ||||

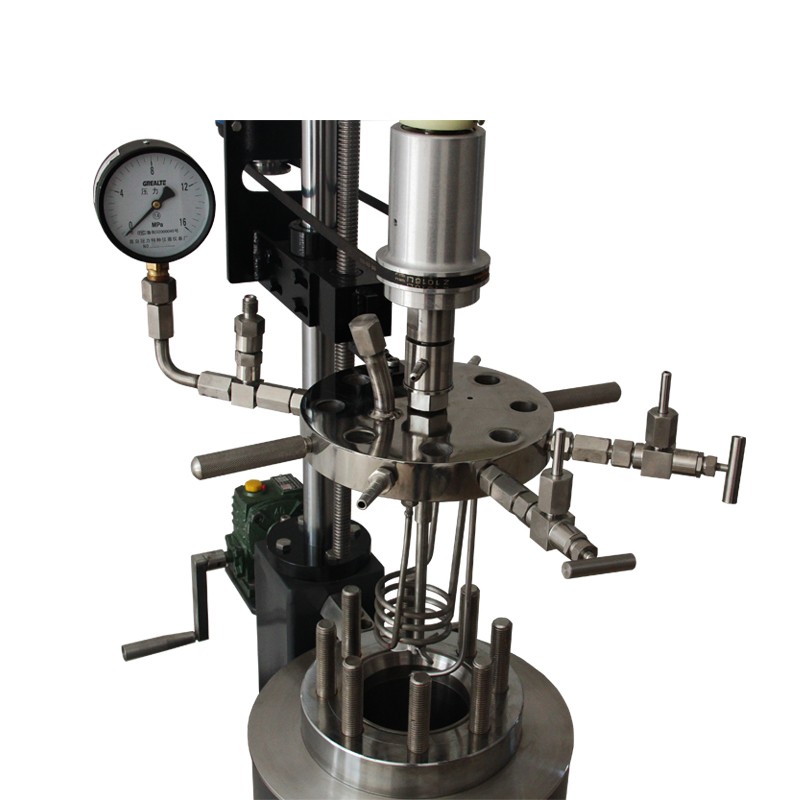

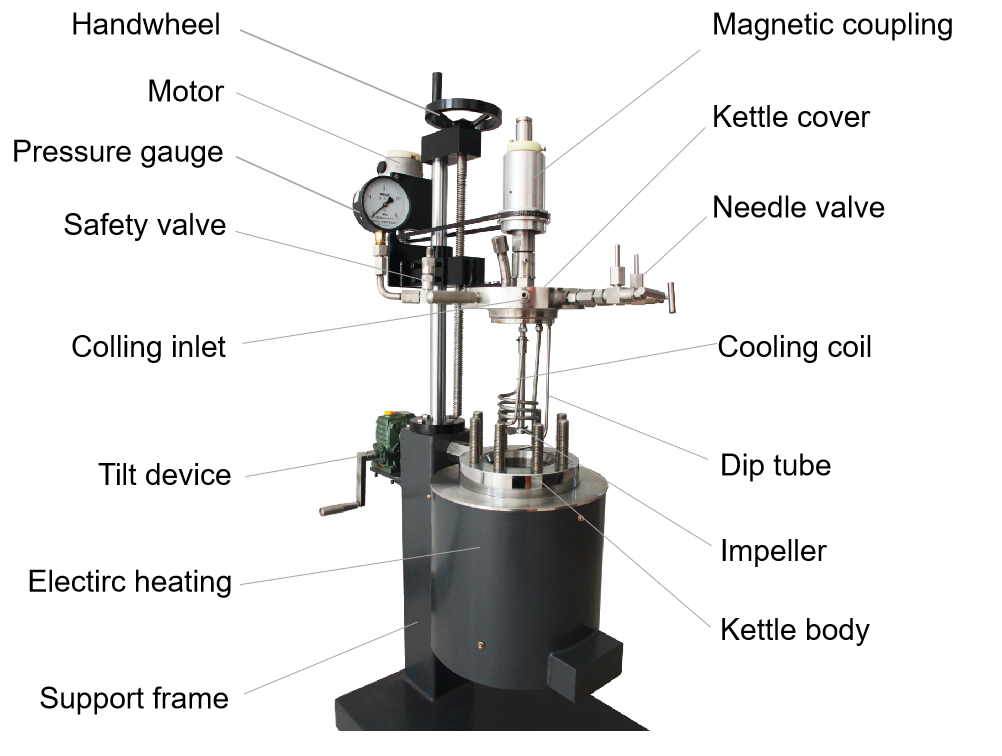

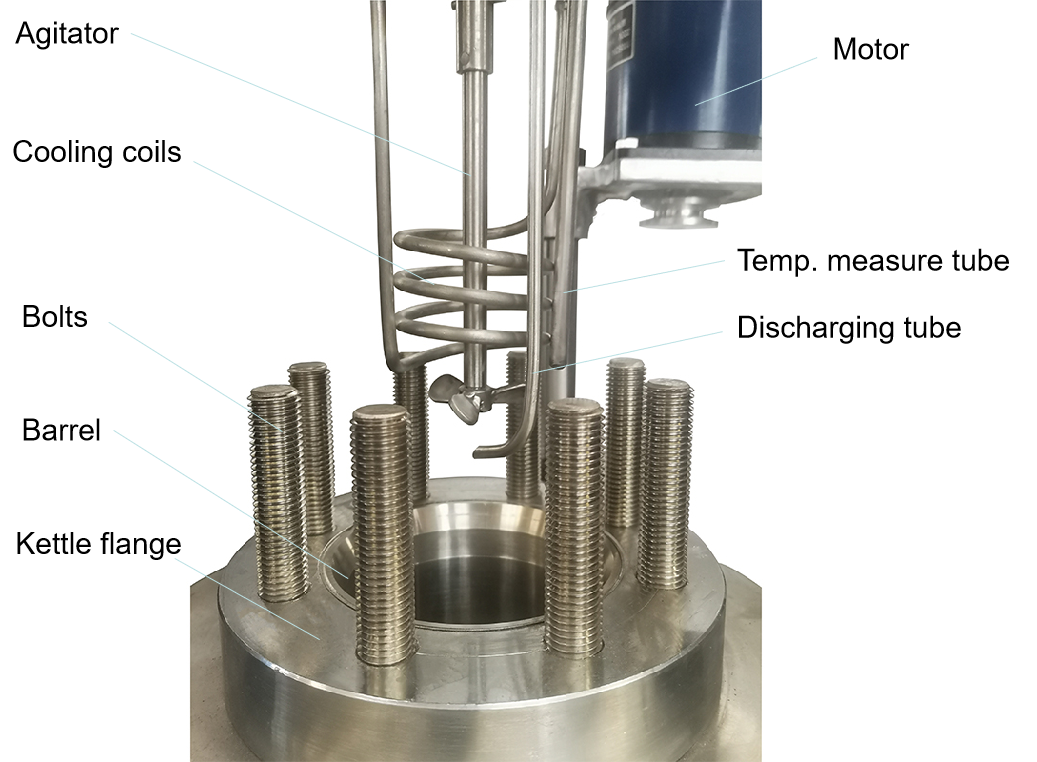

| Standard fittings | Pressure Gage; Thermocouple; Internal Stirring System Liquid inlet and gas inlet with needle valve;Gas Release Valve Dip Tube; Safety Rupture Disc; Cooling Coil | ||||

Product Details

Structure Drawings

Control System

Internal Components

Delivery Details

Departure Port: Qingdao Port or Shanghai Port

Time of Delivery:

Name | Est.time (Days) |

Lab instru. | <7 |

Pilot plant | <20 |

Industrial | <40 |

Note:The specific delivery date subject to product specifications and quantity.