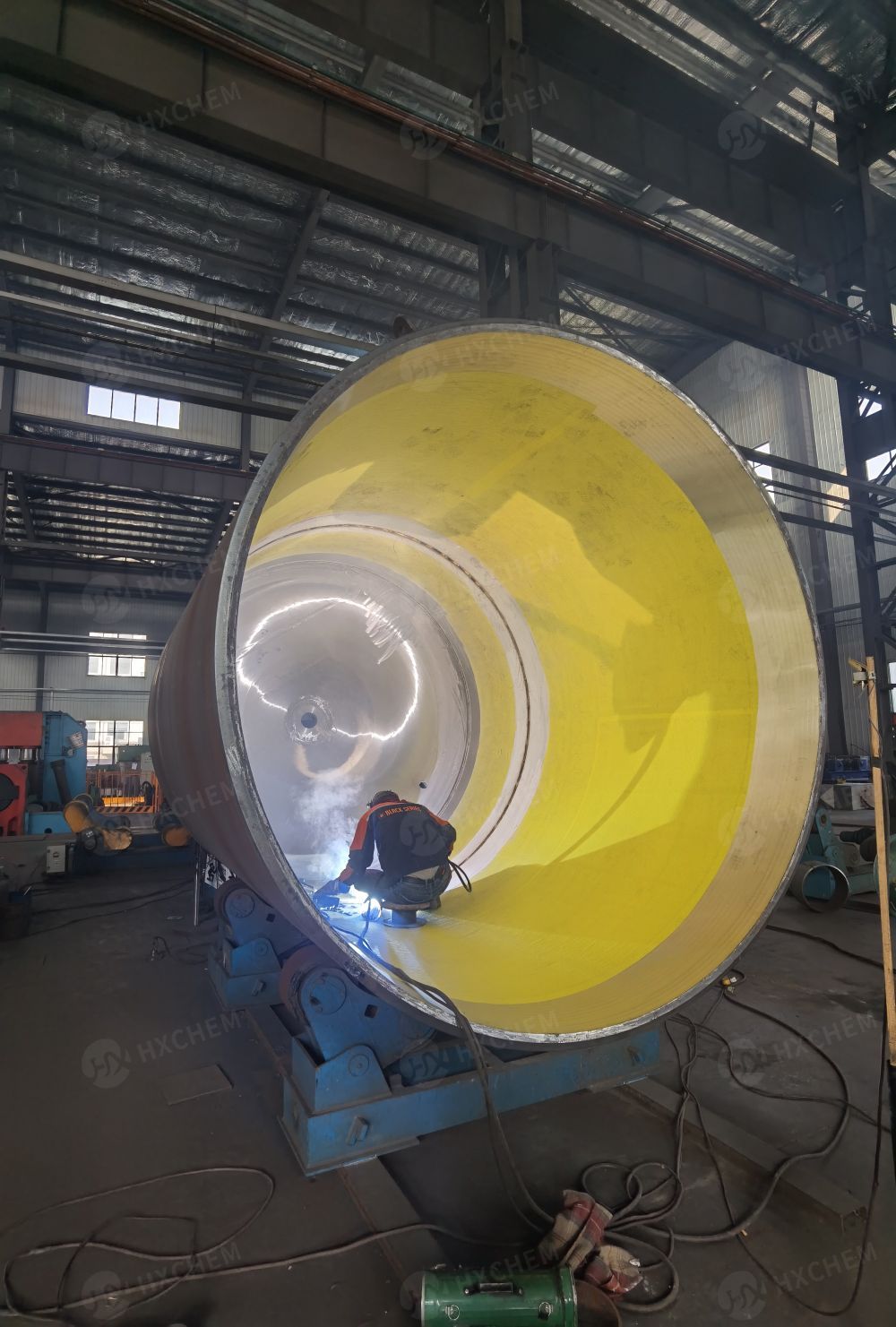

Non Ferrous metal cladding equipment

HXCHEM manufactures heavy wall & non ferrous metal cladding equipment for high pressure and high temperature applications in the Chemical/Petrochemical and Oil & Gas industries. Process equipment properly fabricated from corrosion-resistant alloys can handle extremely corrosive applications. Corrosion-resistant alloys are a distinct category of metals and specialty alloys(Non ferrous metal equipment, Exotic metal equipment) including Titanium, Zirconium, Tantalum, Hastelloy, High Nickel Alloys, as well as the Duplex and Super Stainless Steels.

- HXCHEM

- CHINA

- 50 days after payment

- 10 SETs/MONTH

Details

Non ferrous metal pressure vessel/ Stirred reactor

Introduction

Material of construction

All of our clad equipment is explosion bonded. Explosion cladding is a welding process that uses explosions to bond two dissimilar metals while retaining the mechanical and corrosion properties of both parent metals. The process is most commonly used to clad steel with a thin layer of corrosion-resistant alloy metal, such as as fellows:

√ 316Ti, SS321

√ 310S

√ Titanium

√ Nickel

Non ferrous metal equipement

Fittings and pipes