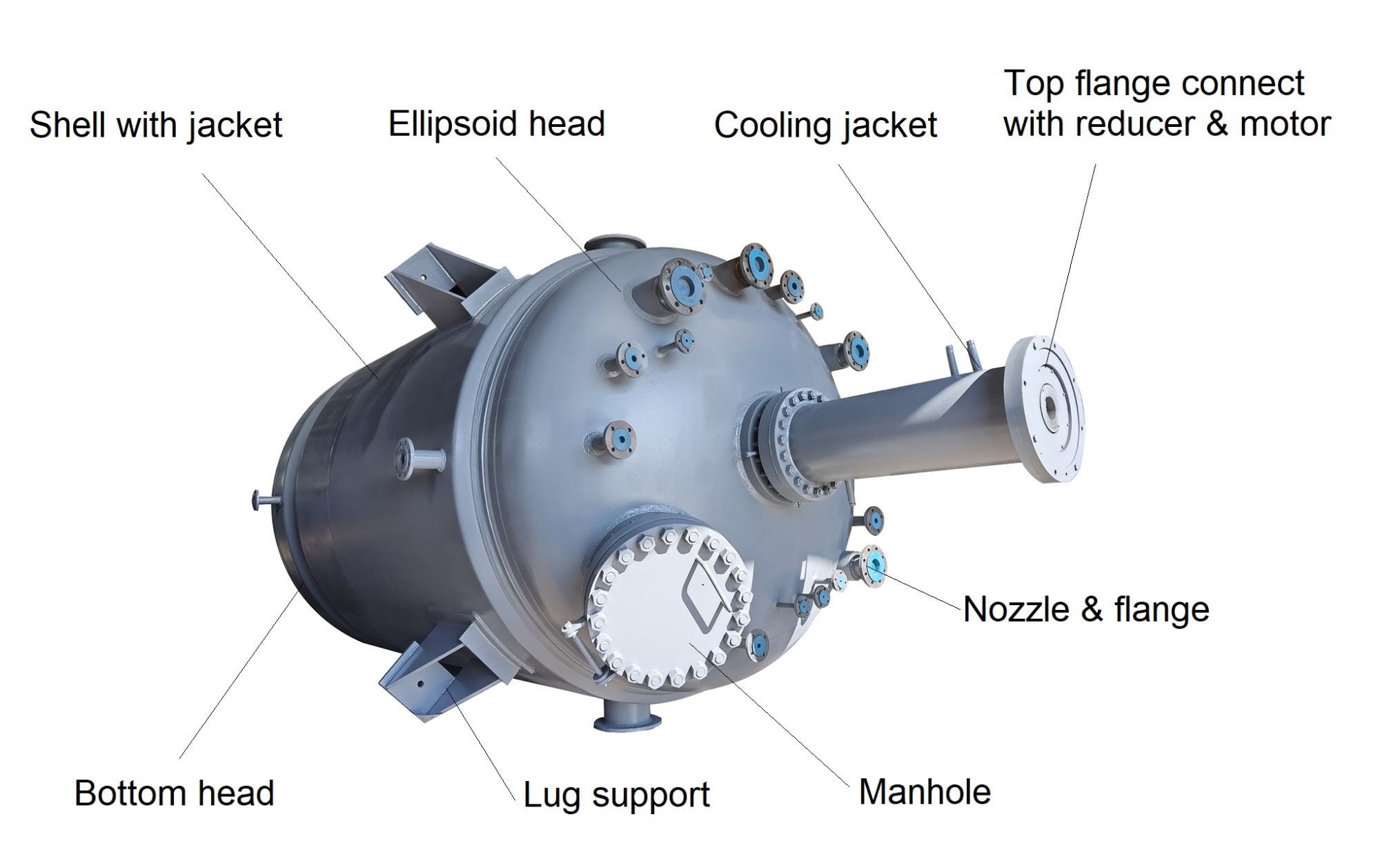

Zeolite molecular sieve crystallization reactor

Molecular sieve catalyst crystallization reactor is specially used in industrial batch, continuous and long period Molecular sieve production. The stainless steel cladding crystailliation reactor we produce are mixed with special mixing blades, which are loaded in different stages of the reaction, especially in the chemical industry, by being subjected to heating or cooling process, Batch Reactor, Chemical Reactor, under a mixture of pressure or vacuum at a certain temperature, under certain temperatures. are the systems where it is provided.

- hxchem

- china

- 60 days after payment

- 15sets/ month

Details

Crystallization reactor

INTRODUCTION

The synthesis methods of Zeolite molecular sieve mainly include three traditional methods including Hydrothermal synthesis , gas-solid method and solid-like method (also called wetting method). Hydrothermal synthesis is the most common and effective way in the synthesis of Zeolite molecular sieve.

The basic process steps of crystallization:

Re-polymerization of polysilicate and aluminate, molecular sieve nucleating, nucleating growth, molecular sieve crystal growth and secondary nucleating.

HXCHEM supply customized crystallization reactor; High pressure crystallization reactor; crystallization autoclave; Stainless steel crystallization reactor; equipped for molecular sieve production.

FEATURES

Volume: 2kl, 3kl, 6kl, 8kl, 10kl, 15kl, 20kl, 30kl;

Design pressure: 16bar; 25bar; 55bar; 65bar;

Design temperature: 250 Celsius degree;

Material: SS316L+ Q345R(Carbon steel);

Shaft seal: Magnetic seal/ Double end mechanical seal;

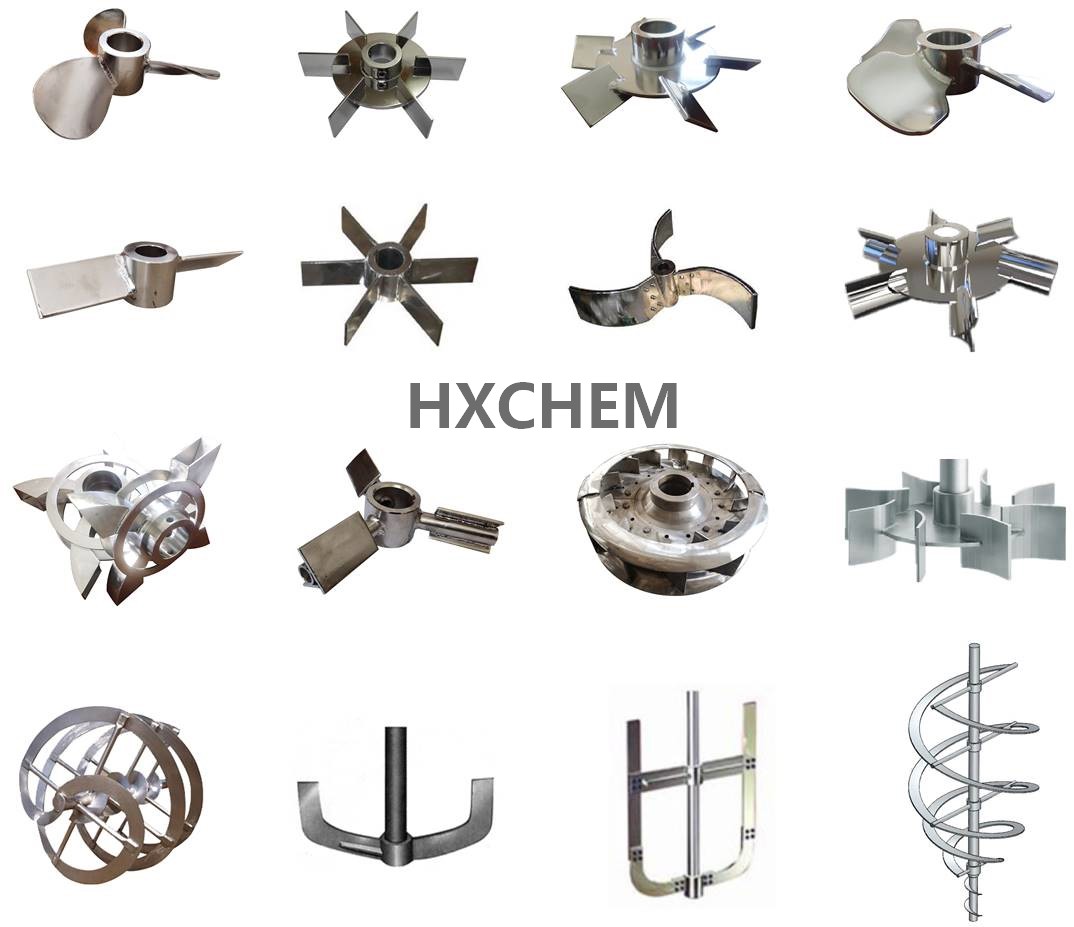

Impeller: Back curve turbine; paddle+ frame impeller, etc.

Back curve turbine agitator & paddle+frame agitator applicate in crystallization autoclave