Industrial gas induction reactor

This series gas induction reactor are mainly for hydrogenation, HXCHEM self-aspiring stirring technology has complete gas consumption,high productivity and uniform suspension of the catalyst. Gas induction reactor;Gas self inducing reactors; Gas inducing reactors; Hydrogenation reactor with hollow gas induction impellers

- HXCHEM

- China

- 45 days after payment

- 15 sets/month

Details

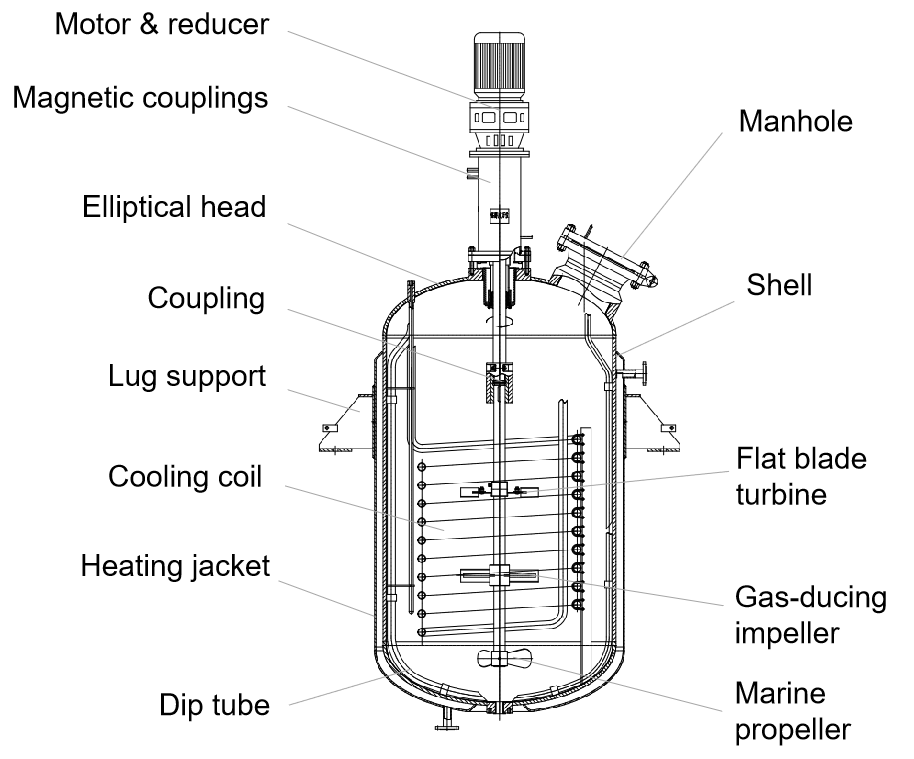

Industrial Gas Induction Reactor

Introduction

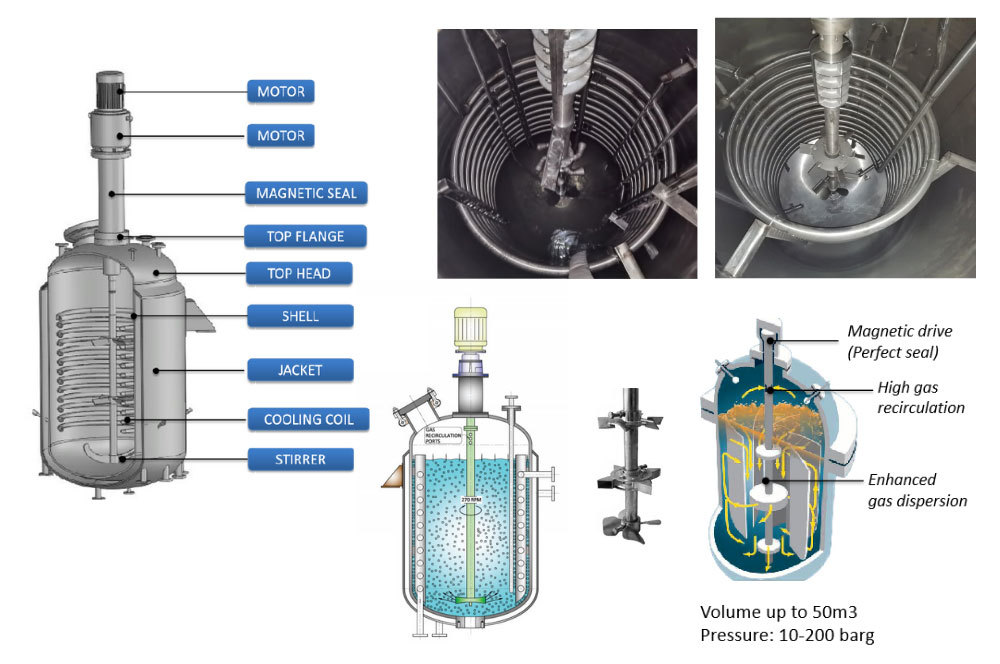

The gas induction reactors(Hydrogenation) usually involves a three-phase slurry, the solid catalyst in slurry phase and the hydrogen bubbles as the gas phase. As there are a number of phase boundaries the mass transfer, and especially the hydrogen dispersion, is a very factor. The mixing system that is employed in the reactor influences the mass transfer coefficient of the gas-liquid transfer greatly. Applications: Hydrogenation – Chlorination – Oxidation – Acylation – Alkoxylation – Amination – Carboxylation

Gas inducing reactors | Gas self inducing reactors | Gas Liquid reactor | Hydrogenation reactor with hollow gas induction impellers

Product Features

? Large scale production gas induction reactors.

? Max pressure: 200 bar; Max temperature up to 350 ℃

? Available material:SS304, SS316, Titanium, Nickel, Hastelloy B/C, Monel, Zirconium, Inconel.

? When the pressure is large, cladding plates could be considered, including base material for strength and clad material for anti-corrosion. Reduce costs for you!

? Low to high torque magnetic couplings: static seal with no leakage.

? Complete gas consumption; High productivity; Uniform suspension of the catalyst.

? Hollow shaft with gas self-inducing impeller; Flat blade turbine impeller; Axial impeller.

Instead of churning the liquid reaction mass, a hollow agitator pumps gases from the head space to the lowest part of the reactor vessel. Hollow shaft with high mass transfer gas induction impeller, pitch blade turbine, axial propeller, paddle etc. The special gas induction impeller vigorously disperses these gases into the bottom of the reactor; Gas bubbles react with liquid/slurry as they rise. Unreacted gases are re-induced into the liquid. The pitch blade turbine breaking Bubbles and the propeller lift and recycle catalyst at the bottom, so as to achieve a a full reaction.

Standard Specifications

Customized Specifications

If there has special process requires,HXHCEM will also customize for you!

Pls list your basis process parameters like follows:

1. Reactor volume

2. Operating Temperature

3. Operating Pressure

4. Reactor Material / contacting components material

5. Agitator type, and the Mixing Speed, motor power request?

6. With heating device or not.

7. Internal cooling coil or not, exchange area?

8. Lifting device or not?

9. Your other requests

......Contact us

We like to help you to accomplish your plans.

Product Details