High temperature electric heating chemical Reactor

High mixing efficiency, work in vacuum or high pressure reaction, accurate high temperature control(300-700℃)! It is widely used for flammable and explosive, highly toxic, precious media, and other highly permeable chemical mediums for stirring reaction. Used in the process of vulcanization and fluoridation of petroleum, chemical, organic synthesis, polymer polymerization. Electric heating chemical reactor; High temperature chemical reactor; Far infrared heating reactor; Induction heating chemical reactors; High temperature resin reactors

- HXCHEM

- China

- 65 days after payment

- 30 sets per month

Details

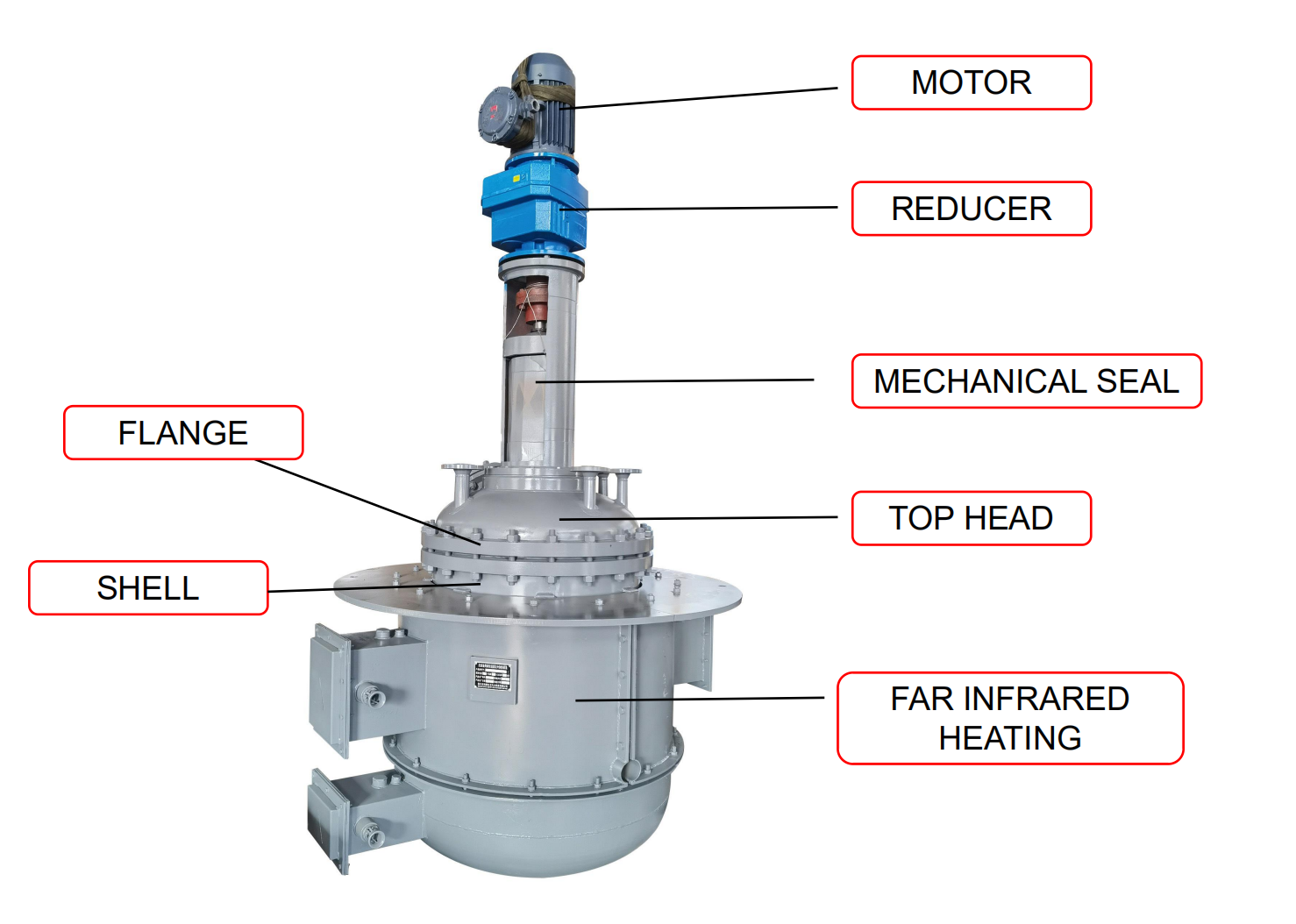

High temperature electric heating chemical Reactor

Introduction

The far-infrared electric heating device has a large heating area, stable and fast heating, uniform heat release, convenient temperature control, and can be controlled by upper, middle and lower sections.

The temperature of the kettle wall in the kettle is easy to control, and there is no side effect on the material in the kettle. No noise, no pollution, long service life (above 30000h), significant energy saving (28% or more). The heater temperature can be arbitrarily set from a normal temperature to 800 °C.

Hydrogenation plants | Pilot lab reactor | Pressure vessel | 100L reactor

Piloclave | Pilot scale jacketed lab reactor | Mini-plant pilot reactor

Application: High temperature reaction, Resin reactors, Polymerization, Crystallization, Synthesis, etc.

| Model | GSH500 |

| Reactor name | Far infrared heating reactor |

| Volume | 500 Liters |

| Pressure | 6 bar |

| Temperature | 450℃ |

| Heating type | Far infrared heating |

| Seal type | Mechanical seal |

| Stirring type | Anchor type |

Product Features

Floor stands or moveable cart type.

Capacity volume: 1liters to 5000 liters.

Pressure: -1~300 bar; Max temperature up to 700 ℃.

Heating:Far-infrared electric heating.

Magnetic seal or mechanical seal.

Available material:SS304, SS316, Titanium, Nickel, Hastelloy B/C, Monel, Zirconium.

Various impeller type available for mixing mission.

Spiral, tube internal condenser available.

Monitor and control: Temperature, pressure, motor speed, operating time, etc.

Customized according to customers requirement.

Details Shows

Customized Specifications

First step:Design

1. Reactor volume

2. Working Temperature

3. Working Pressure

4. Reactor Material / Wetted material

5. Agitator type, and the Mixing Speed, motor power request? Explosion-proof?

6. With heating device or not? Type?

7. Internal cooling coil or not, exchange area?

8. Lifting device or not?(0.5L-500L)

10. Your other requests?

Second step: ConfirmationConfirmation based on customer's request;

Third step: Production

Forth step: Finishing and transportation

Fifth step: Technical Documents and after sale serviceWe like to help you to accomplish your plans.

Production details

HXCHEM provides various electric heating chemical reactor; High temperature chemical reactor; Far infrared heating reactor; Induction heating chemical reactors; High temperature resin reactors, pilot chemical reactors; Electric heating pilot reactors, etc.

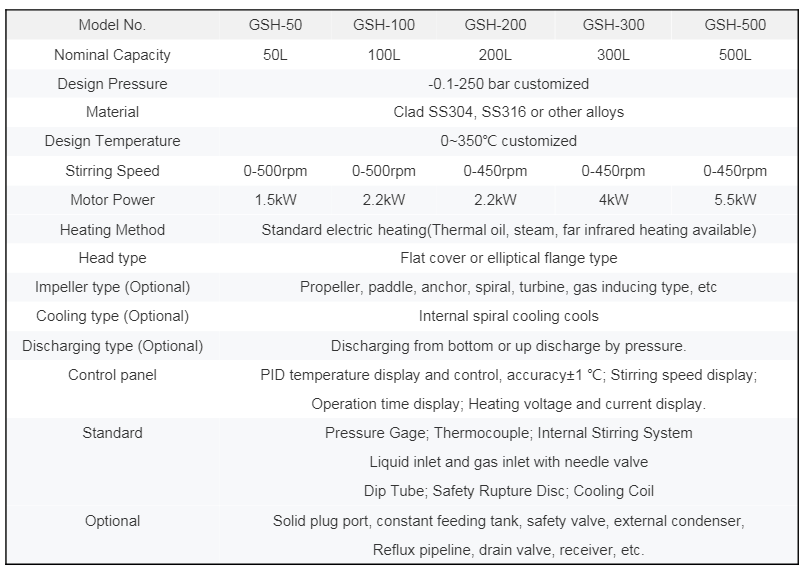

Standard Specifications

Note:The above standard parameters are for reference only. Different processe have their own reasonable selection, not the more complete the function, the better.

The structure, specification, nozzle size and orientation need to be confrimed after communicating with us.