50L Crane Lifting High Pressure Reactor

Applicated in Hydrogenation, Gas liquid reaction, Polymerization, Synthesis, Catalytic, Petrochemical, etc. Different technologies and materials are used, depending on the requested process and process media. Pilot plant & Reactor system | Hydrogenation reactor | Autoclave reactors Voume: 20 - 500liters Pressure: -1(FV) - +350bar Temperature: 20 °C to +350 °C Material: SS304, SS316, other alloys

- HXCHEM

- China

- 30days

- 100sets/month

Details

50L Crane Lifting High Pressure Reactor

Introduction

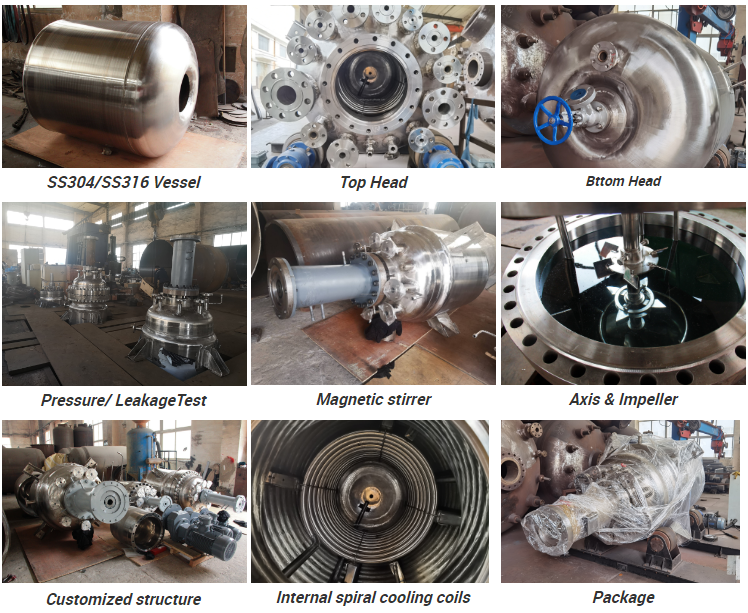

This series is widely used in scale up and small-scale production

Volume: 20-500liters.

Pressure: Standard 100bar, maximum up to 350bar

Temperature: Up to 350℃

Material:SS304, SS316, Hastelloy B/C, Nickel, Titanium, Zirconium, etc.

Heating method:Electric oil heating

Seal type: Magnetic stirrer drives

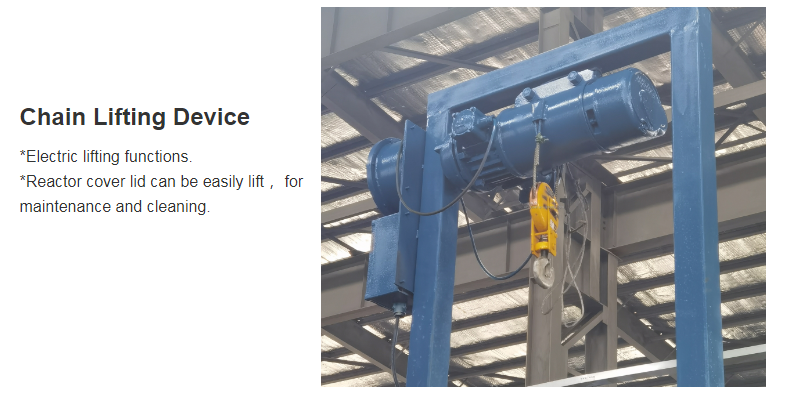

For the design of pilot-scale autoclave and detachable head, the head and container are too heavy to be lifted manually. Therefore, the design with chain pulley support installed can lift the head with minimal effort. When manual operation is still laborious, it can also adopt electric lifting or even hydraulic lifting. HXHCEM will choose the appropriate lifting scheme for you between economy and practicability.

Pilot plant reactor | Pilot scale jacketed lab reactor | Pilot reactor systems | Pilot plant equipment

50L reactor/ 100L reactor | 200L reactor | 300L reactor | 500L reactor

Product Features

? Floor stands or moveable cart type.

? Capacity volume: 10 liters to 50 liters.

? Pressure: -1~300 bar; Max temperature up to 350 ℃

? Low to high torque magnetic couplings: static seal with no leakage.

? Chain pulley lifting device for reactor head rising and lowering (Electric lifting and hydraulic lifting available)

? Available material:SS304, SS316, Titanium, Nickel, Hastelloy B/C, Monel, Zirconium, Inconel, Tantalum.

? Monitor and control: Temperature, pressure, motor speed, operating time, etc.

? Customized according to customers requirement.

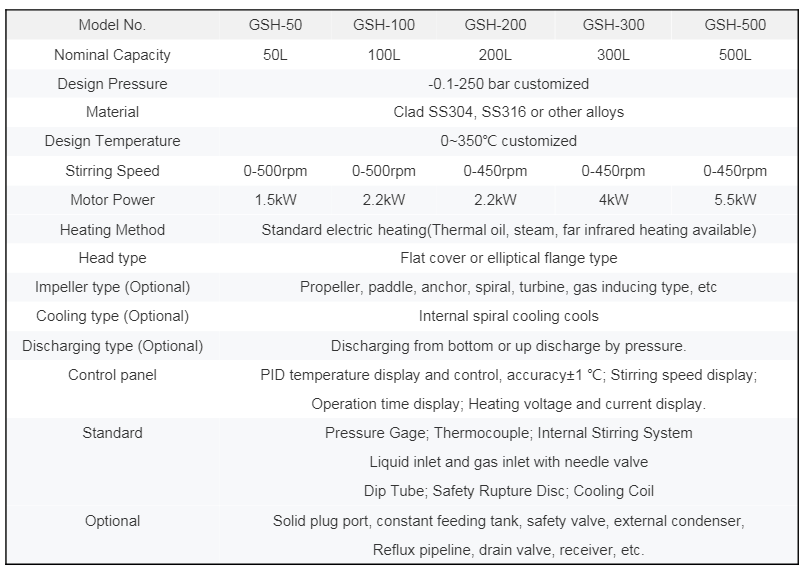

Standard Specifications

Note:The above standard parameters are for reference only. Different processe have their own reasonable selection, not the more complete the function, the better.

The structure, specification, nozzle size and orientation need to be confrimed after communicating with us.

Customized Specifications

If there has special process requires,HXHCEM will also customize for you!

Pls list your basis process parameters like follows:

1. Reactor volume

2. Operating Temperature

3. Operating Pressure

4. Reactor Material / contacting components material

5. Agitator type, and the Mixing Speed, motor power request?

6. With heating device or not.

7. Internal cooling coil or not, exchange area?

8. Lifting device or not?

9. Your other requests

......Contact us

We like to help you to accomplish your plans.

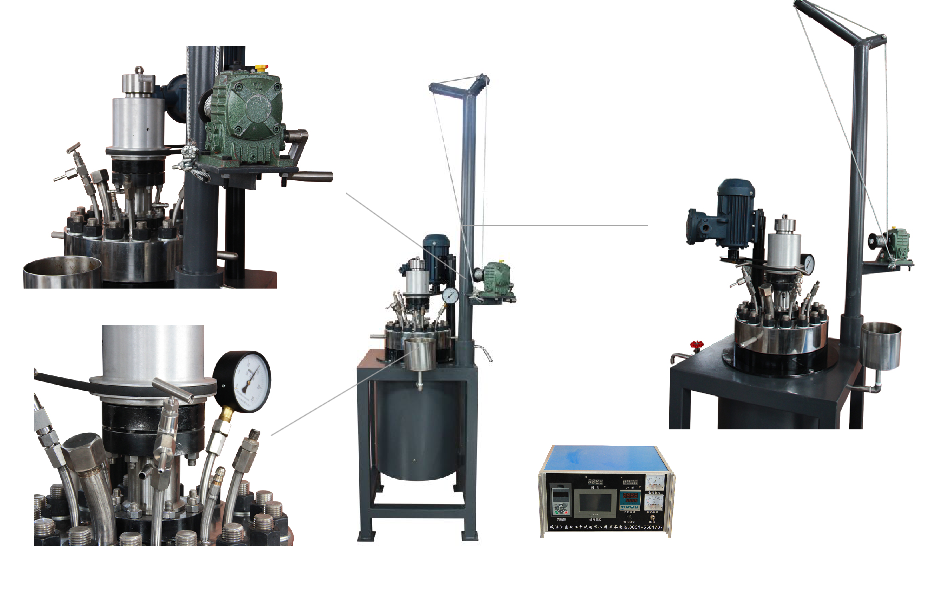

Product Details

Structure Drawings

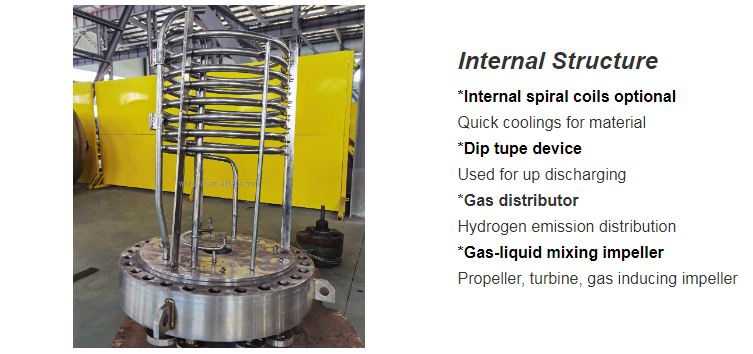

Internal Components

Delivery Details

Departure Port: Qingdao Port or Shanghai Port

Time of Delivery:

Name | Est.time (Days) |

Lab instru. | <7 |

Pilot plant | <20 |

Industrial | <40 |

Note:The specific delivery date subject to product specifications and quantity.

Payment Terms:

Payment amount | ≤10000USD | >10000USD |

Payment term | 100% TT in advance | 40% T/T in advance, balance before shippment. |

Other type | Paypal;Alibaba | 100% Irrevocable L/C at Sight |

Note: The specific payment terms will be confirmed through negotiation.

Package type:

Wooden Box Packaging (Standard export package)

Application: By air; LCL(Less container loading) by sea.

Details:The product will be covered by PE film, then packed in plywood case. If necessary, steel frame outside support and steel wire inside fixing.