Cladded SS316Ti reactors

SS316Ti reactors; Cladded SS316Ti reactors;SS316Ti pressure reactors; SS316Ti Cladded reactors; SS316Ti cladding reactors; SS316Ti reactor vessels; Internal cooling coil, vent port, liquid / powder charging, dip tube, thermowell, safety rupture disc, pressure safety valve, flush bottom outlet, baffles, light & sight glass, handhole / manhole etc. Nozzles, manual / automated valves, fittings, control panel & accessories offered based on requirement.

- HXCHEM

- China

- 45 days after payment

- 5sets/ month

Details

Cladded SS316Ti reactors

Introduction

Stainless Steel Grade 1.4571/316Ti contains a small amount of titanium. Titanium content is typically only around 0.5%. The titanium atoms stabilise the structure of the 316 at temperatures over 800°C. This prevents carbide precipitation at the grain boundaries and protects the metal from corrosion.

Volume: 1000-30000 liters.

Design pressure: maximum up to 150bar

Design temperature: Up to 350℃

Material:SS316Ti.

Jacket type: Full jacket, half pipe jacket

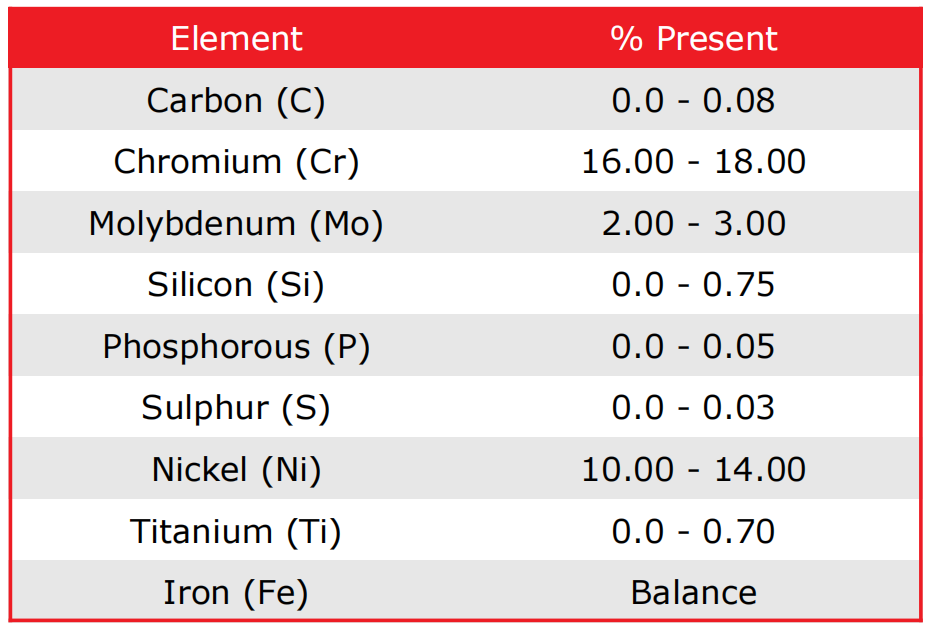

Component composition

Proof stress: 170MPa; Tensile strength:485MPa

Grade 316 has excellent corrosion resistance when exposed to a range of corrosive environments and media. It is usually regarded as “marine grade” stainless steel but is not resistant to warm sea water.

Warm chloride environments can cause pitting and crevice corrosion. Grade 316 is also subject to stress corrosion cracking above around 60°C.