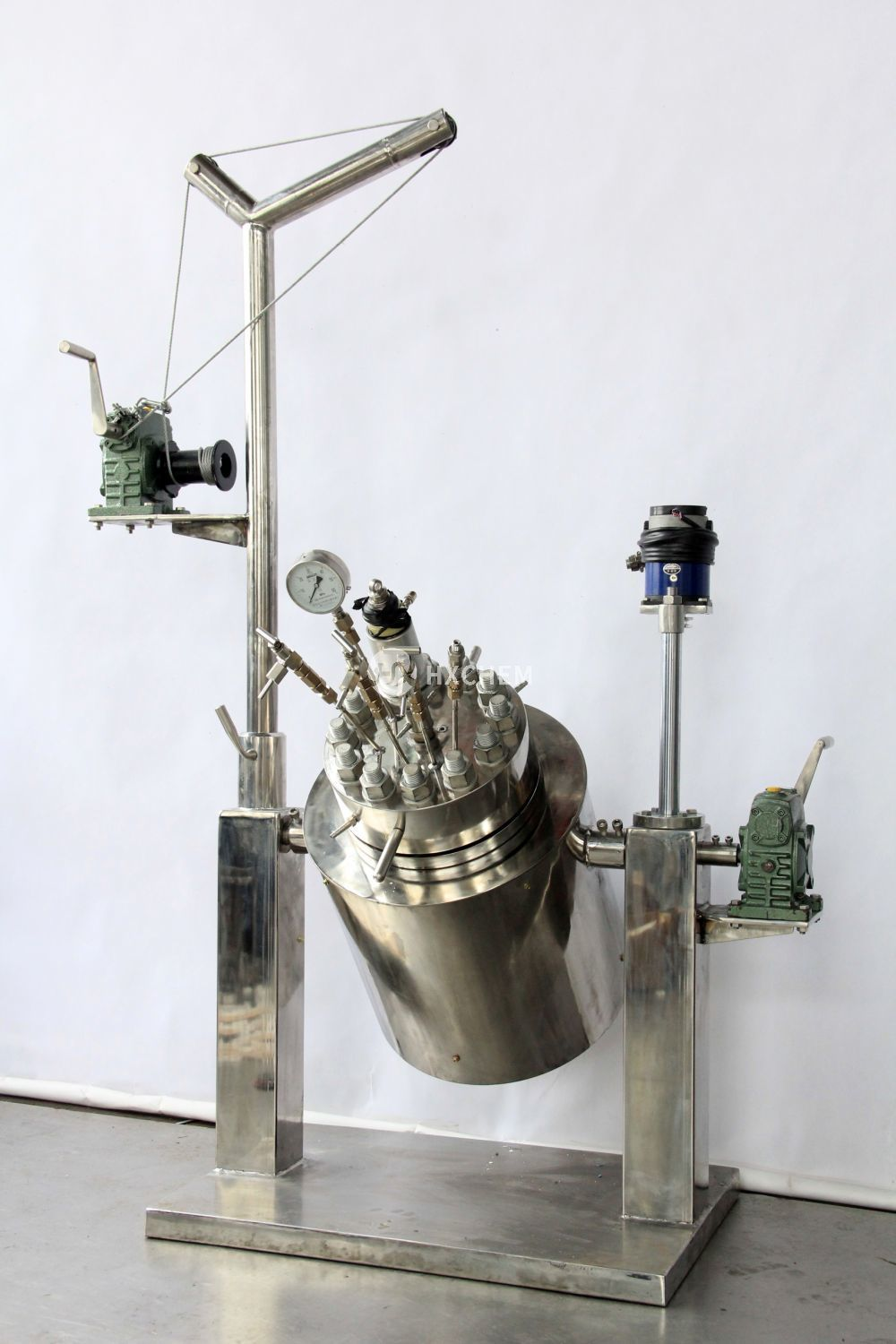

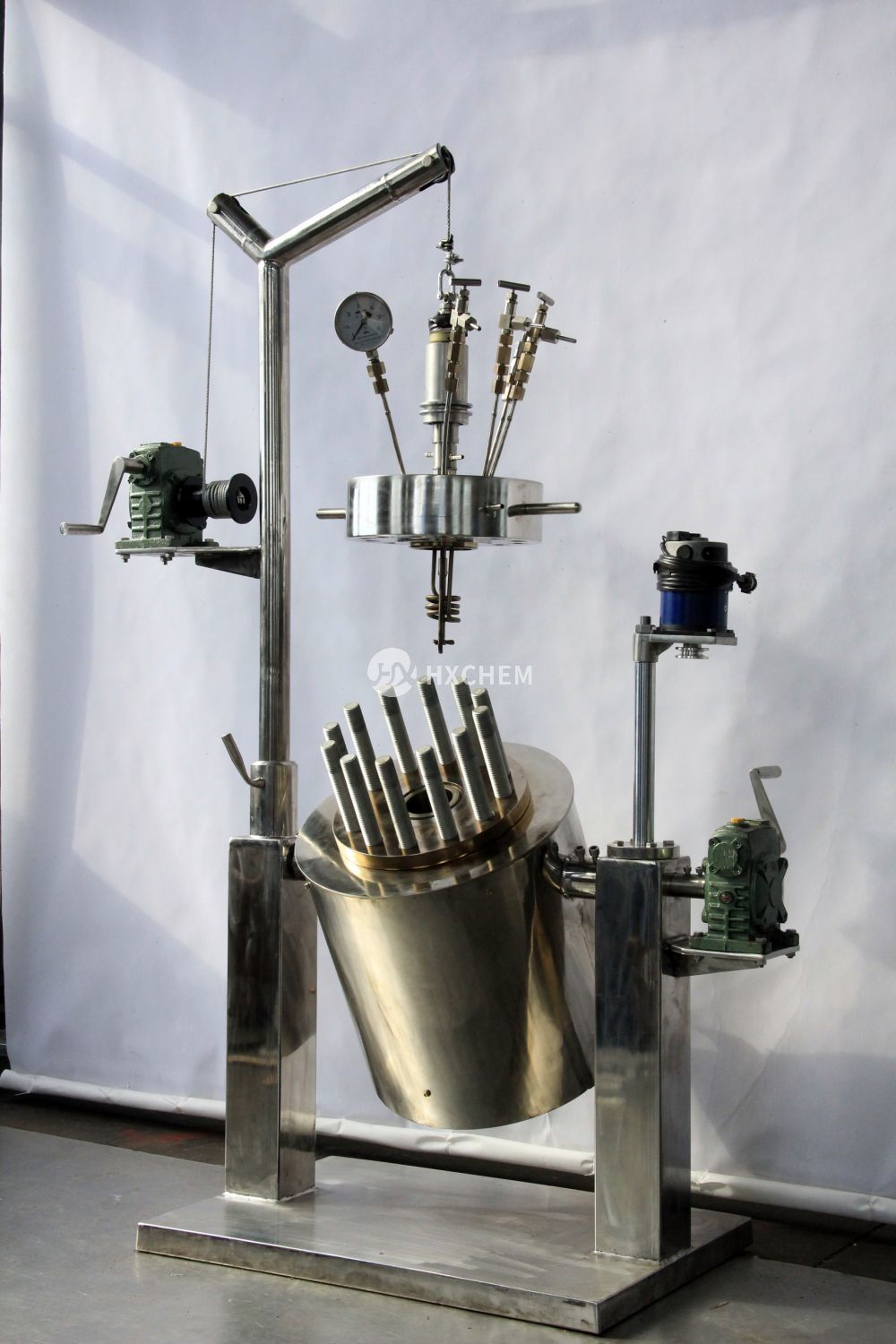

5L 200bar floor stand bolted closure laboratory batch reactors

Reactor volume: 5.0 liter Maximum Pressure: 200 bar Temperature: 20 °C to +300 °C Material: Stainless steel 304/316 Features: Vessel body can be tilting Top cover lid can be rising & lowering 5liters pressure reactors;laboratory batch reactors; laboratory reactors

- HXCHEM

- CHINA

- 20 days after payment

- 30 SETS PER MONTH

Details

Floor stand bolted closure laboratory pressure reactors

Top cover lid manual lifting & Vessel body rotation

Product Introduction

Lab high temperature high pressure reactors

Reactor volume: 500ml, 1liters, 2liters, 5liter

Maximum Pressure: 0-350 bar

Temperature: 20 °C to +400 °C

Material: Stainless steel 304/316, C276, Titanium, etc

Features: Vessel body can be tilting

Top cover lid can be lifting & lowering

Other materials, pressures & temperatures are available.

Features

Flat cover lid: Lifting & lowering

Closure type: Flange type with bolts closure

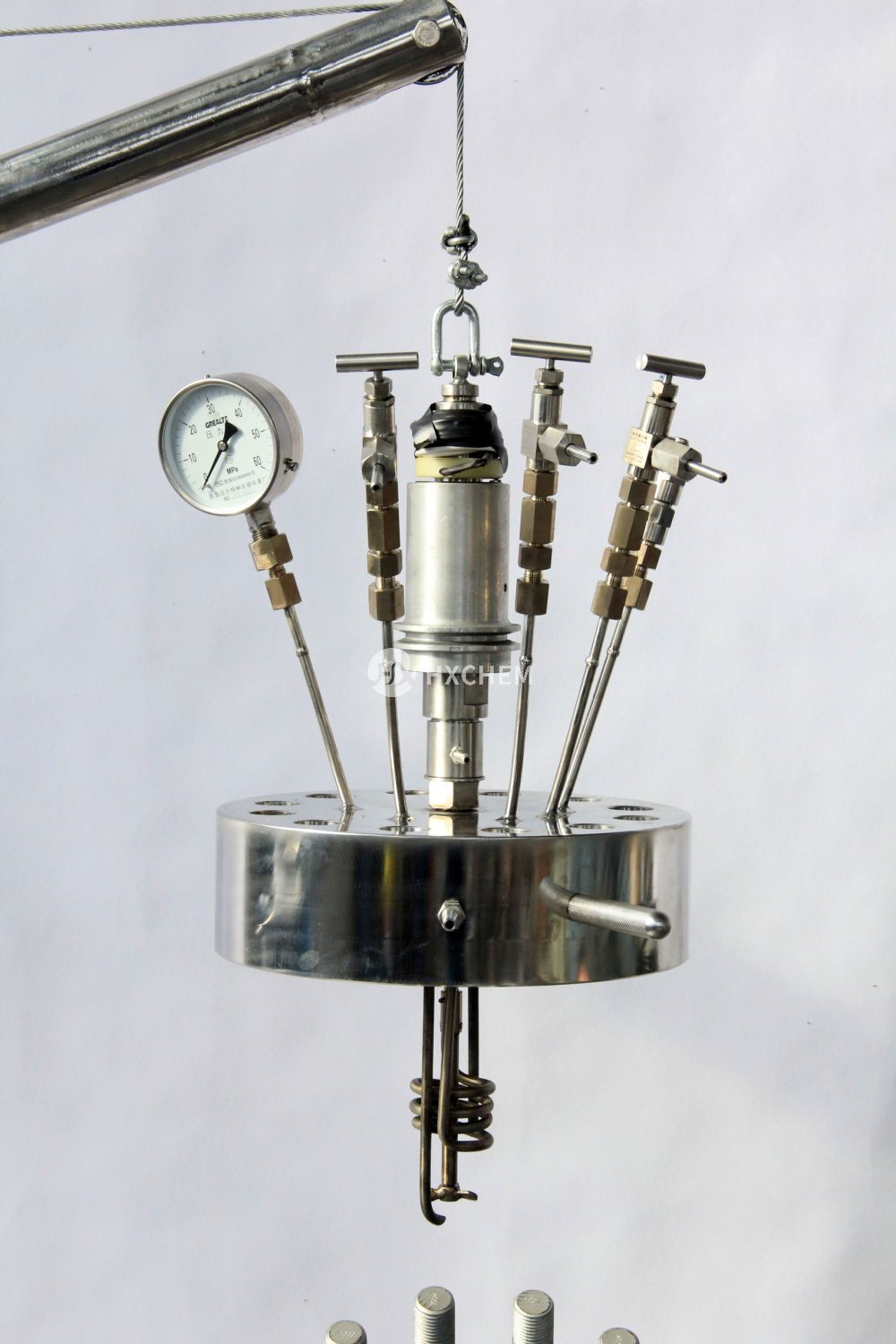

Shaft seal: Magnetic coupling drive

Reactor vessel: Tilting

Control: PID temperature control.

Specification

QUICK SELECTION(0.5liters to 5 liters) | |||||

Model No. | GSHK-0.5 | GSHK-1 | GSHK-2 | GSHK-3 | GSHK-5 |

Nominal Capacity (L) | 0.5 | 1 | 2 | 3 | 5 |

Working Pressure (MPa) | 10 | 10 | 10 | 10 | 10 |

Working Temperature (℃) | 350 | 350 | 350 | 350 | 350 |

Stirring Speed (r/min) | 0-1500 | 0-1500 | 0-1500 | 0-1500 | 0-1500 |

Motor power (kW) | 0.15 | 0.2 | 0.2 | 0.2 | 0.6 |

Heating Power (kW) | 1 | 2 | 2 | 3 | 4 |

Material | SS304 or SS316 | ||||

Heating Method | General electric heating | ||||

Cooling Method | Internal spiral coils | ||||

Charging Method | Charging from above | ||||

Stirring type | Propeller, paddle type, anchor type or customized | ||||

Control panel | Temperature, time and heating voltage display | ||||

Standard fittings | Pressure Gage; Thermocouple; Internal Stirring System | ||||

Product Details

Applications

These reactors are used in many branches of chemical technology. Catalytic Hydrogenation with its associated catalyst development and testing is certainly one of the principal applications of these reactors with their excellent three phase mixing designs. Polymer development is another major area of application. Additionally, the vessels have been used extensively in hydrometallurgical applications. Hydrogenation, Catalyst Screening / Testing; Polymerization; Styrene Butadiene; Alkoxylation; Distillation; Ethoxylation; Hydrocracking; Dehydrogenation; Oxidation; Fischer TrophCarboxylation; Fluid Catalytic Cracking; Biojet Fuel production; Crystalization.